EVOLT

Your Partner

In Precision

Manufacturing

With our close to 20 year engineering and precision manufacturing experience – primarily relying on indexed and simultaneous 5-axis millling strategies – we are an efficient and reliable partner in the field of manufacturing the following parts:

Our everyday life is value creation!

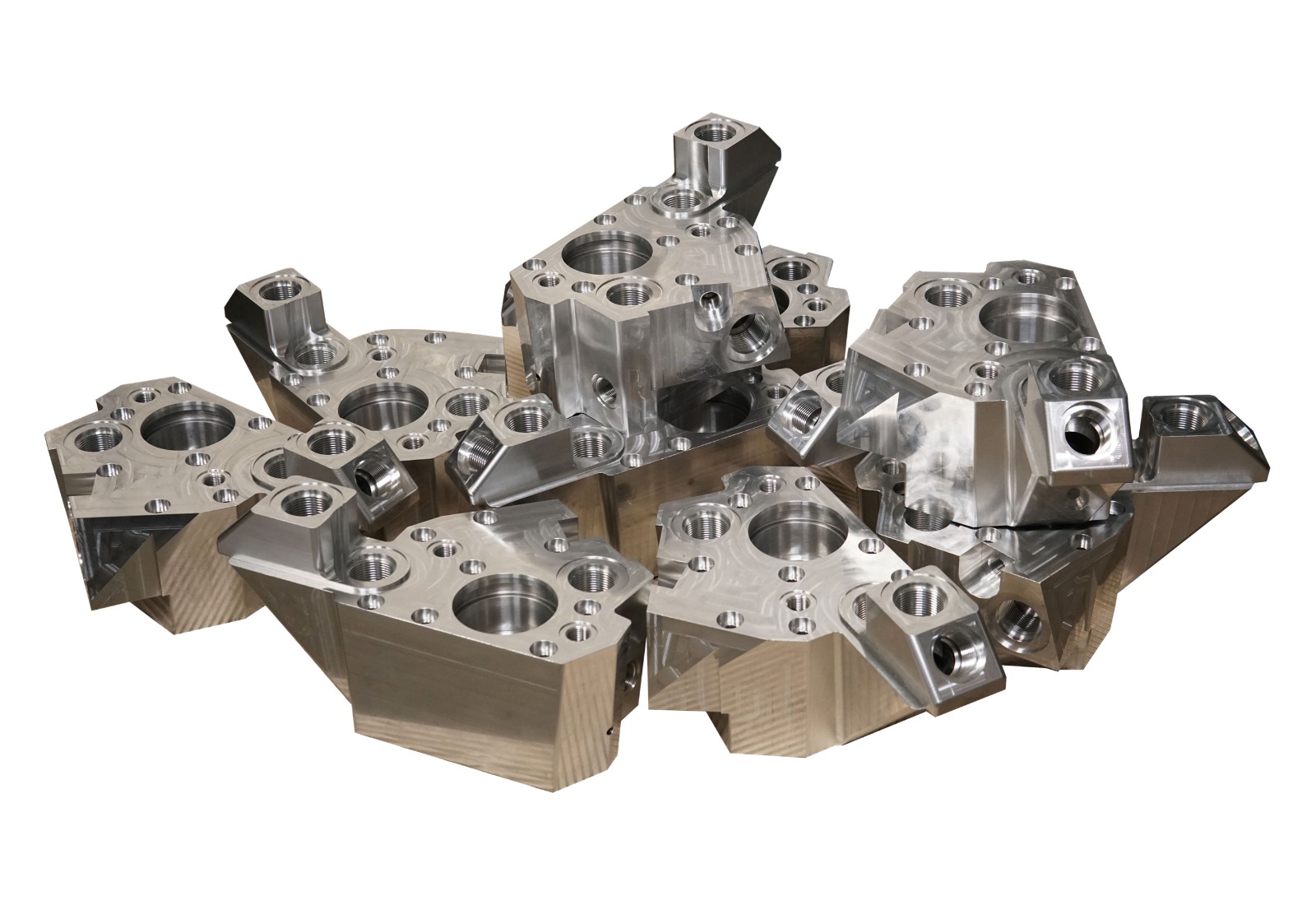

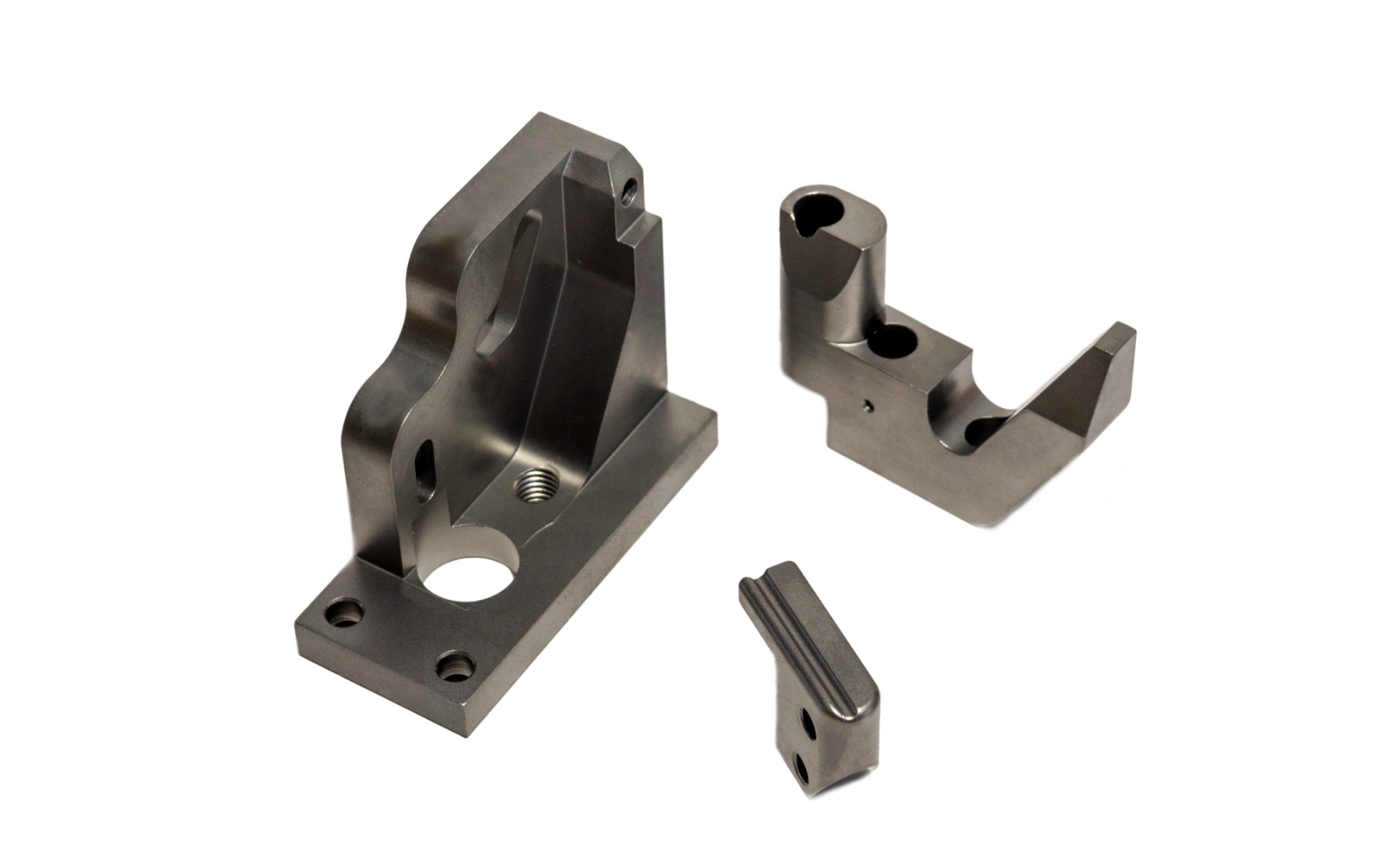

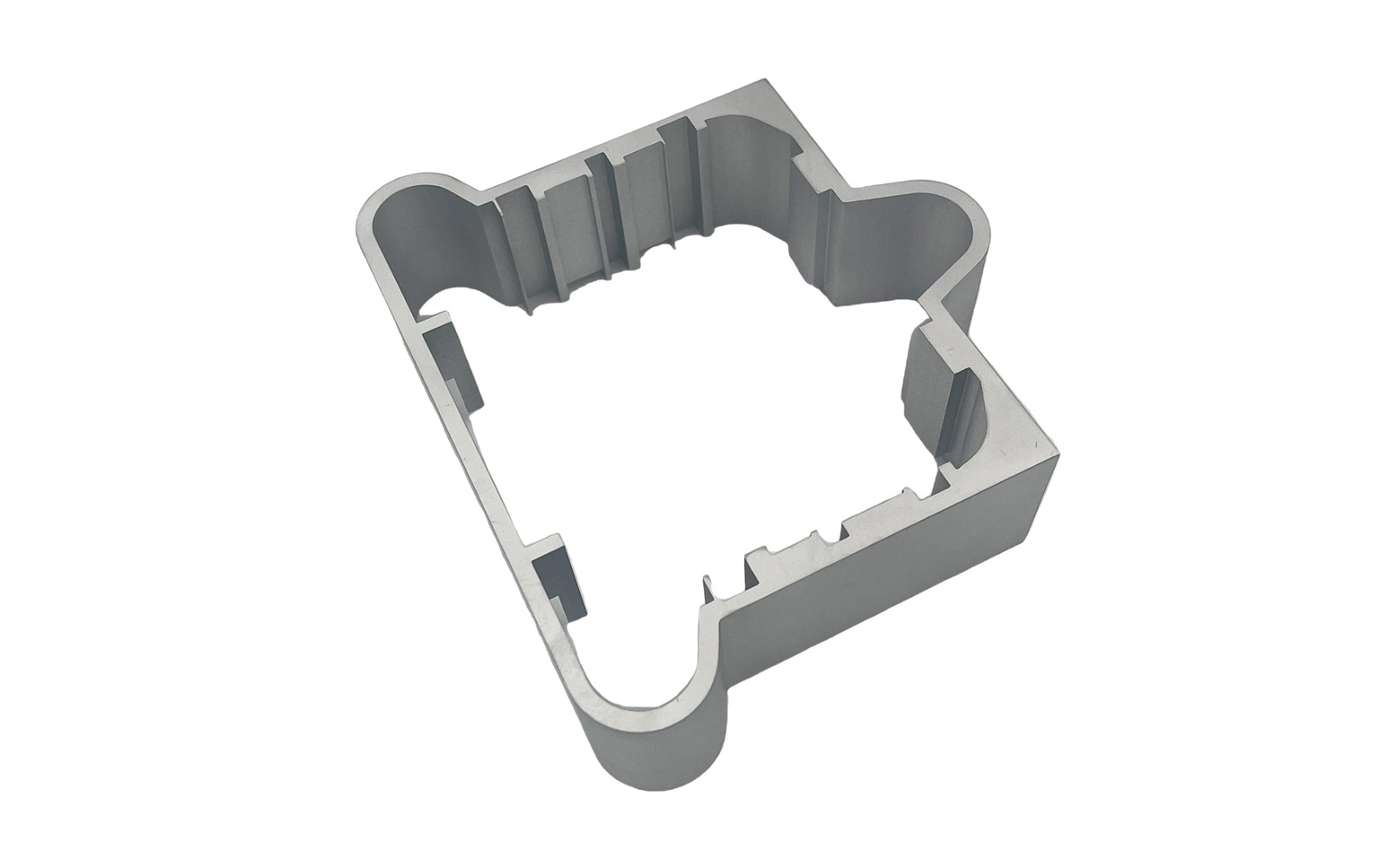

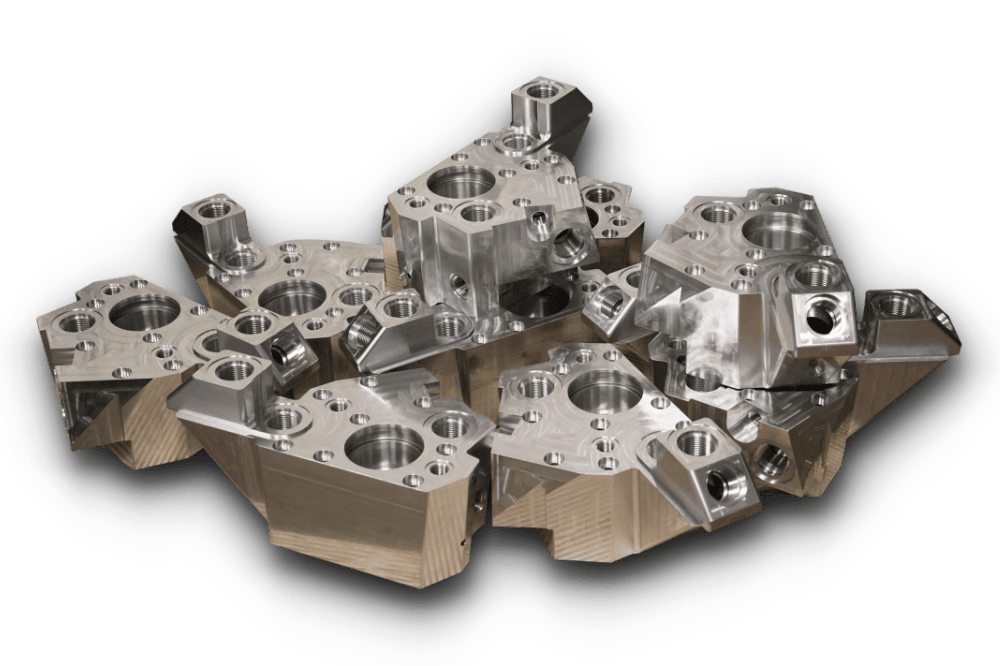

- KParts of complex geometry,

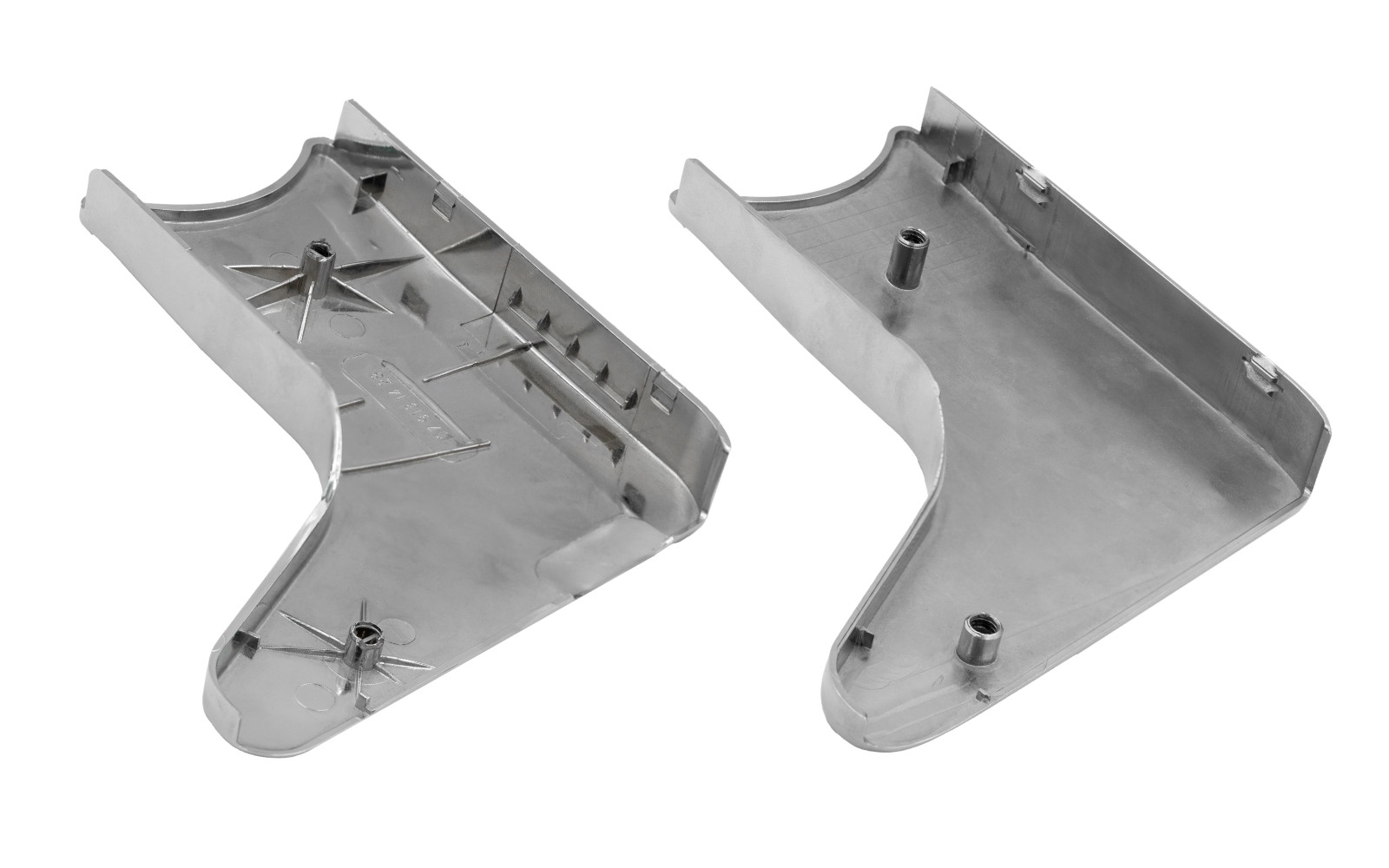

- KMade with 5-axis simultaneous milling, welded, assembled custom parts,

- KReplacement parts, spare parts,

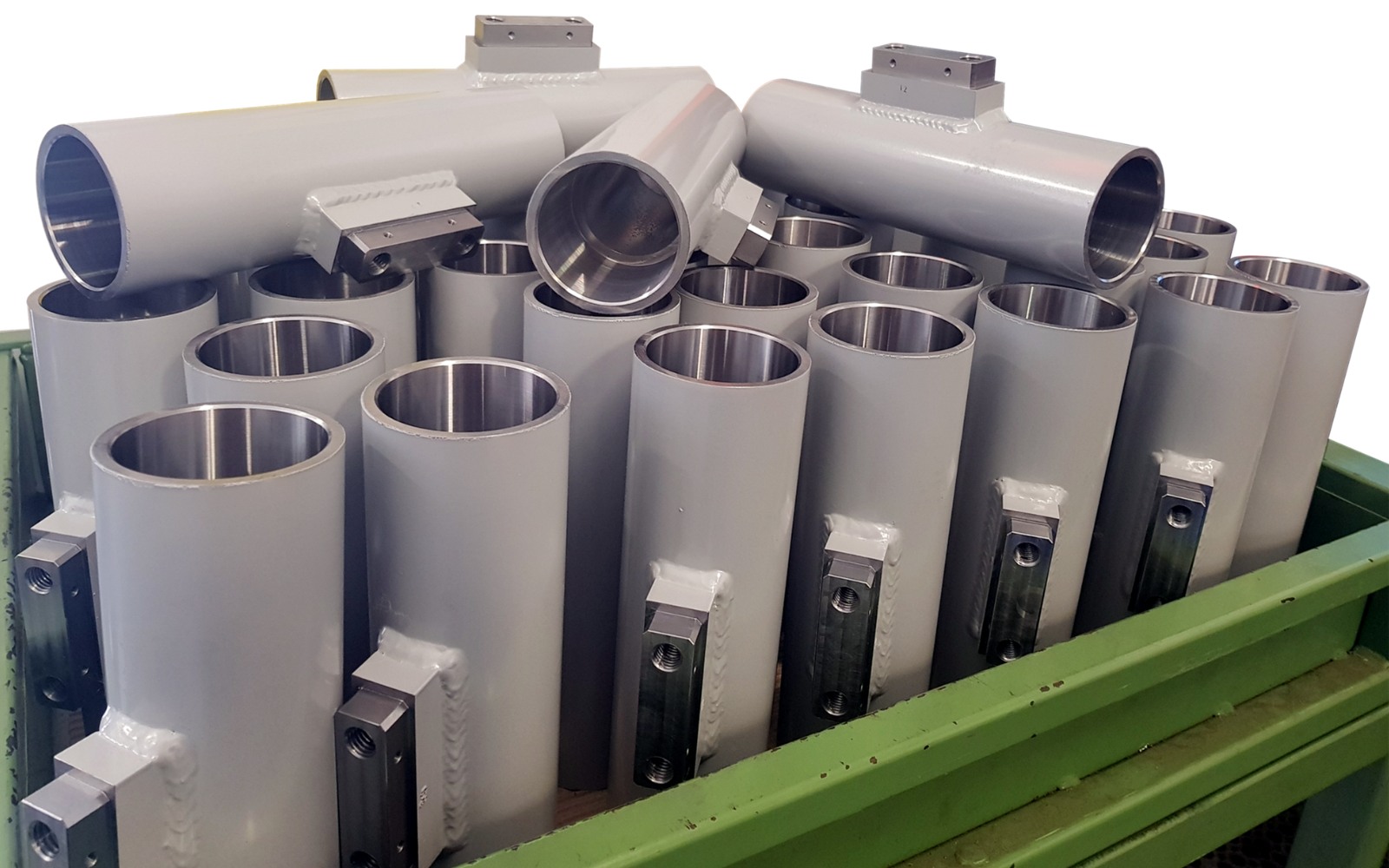

- KComponents of devices,

- KSample items, prototypes,

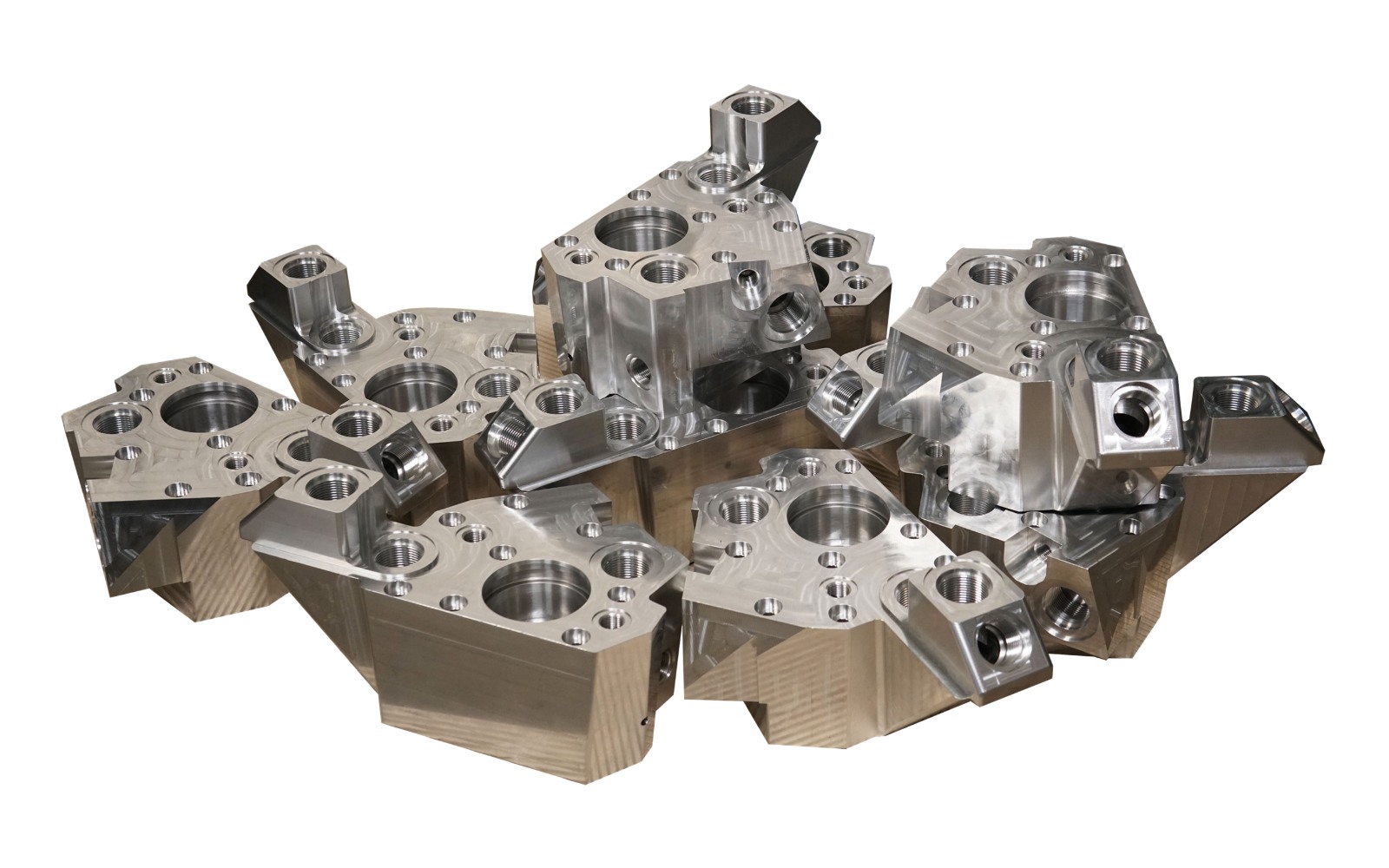

- KDistribution blocks,

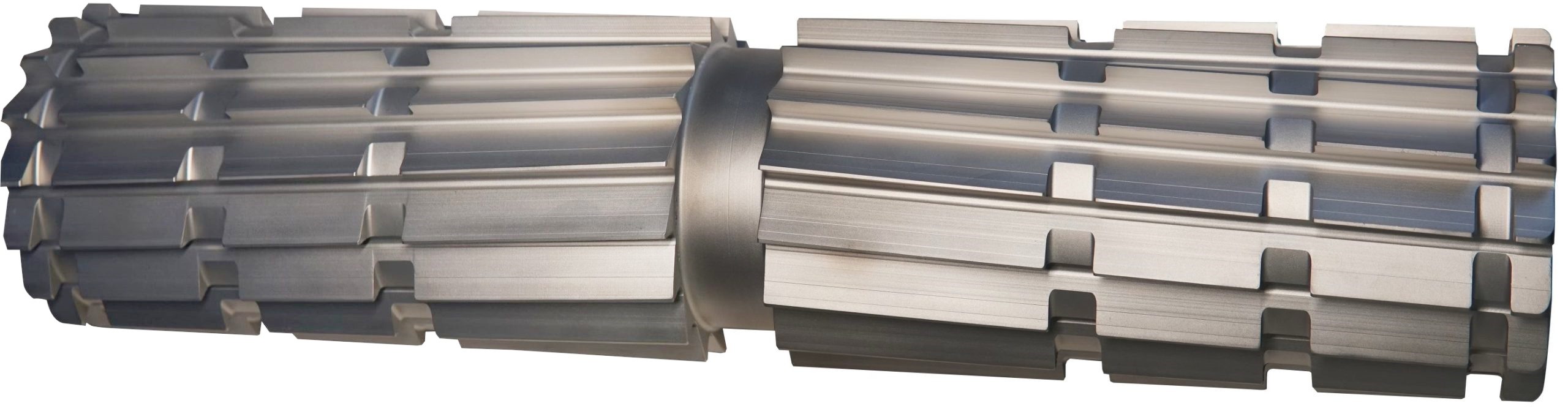

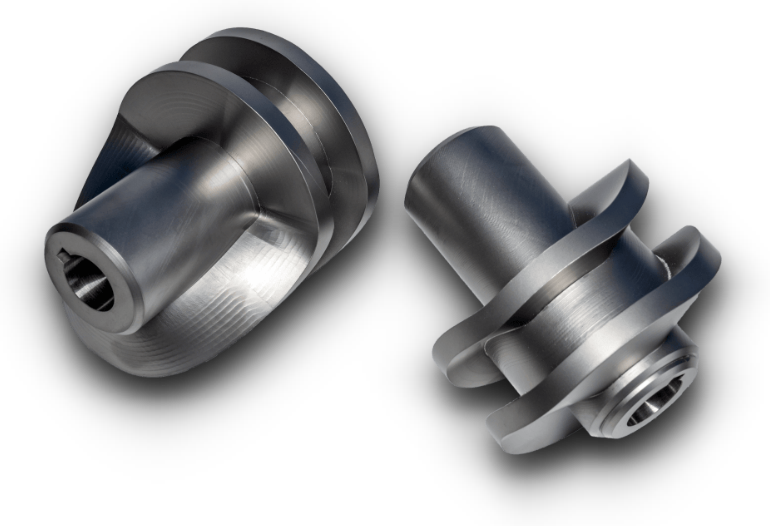

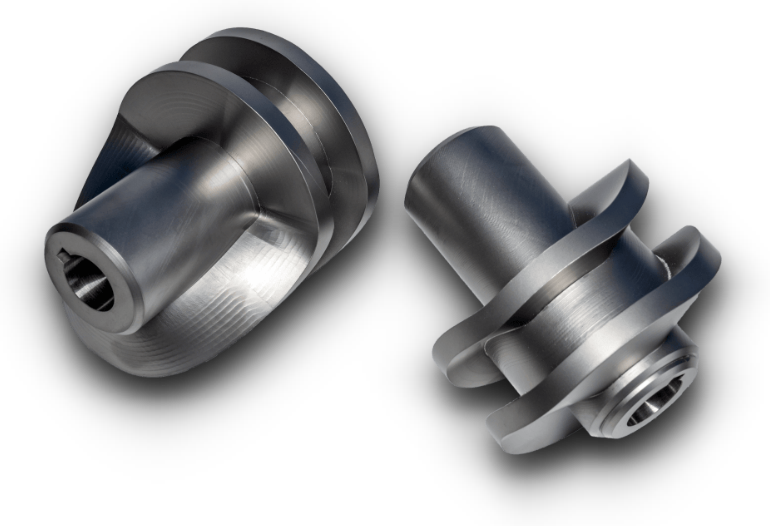

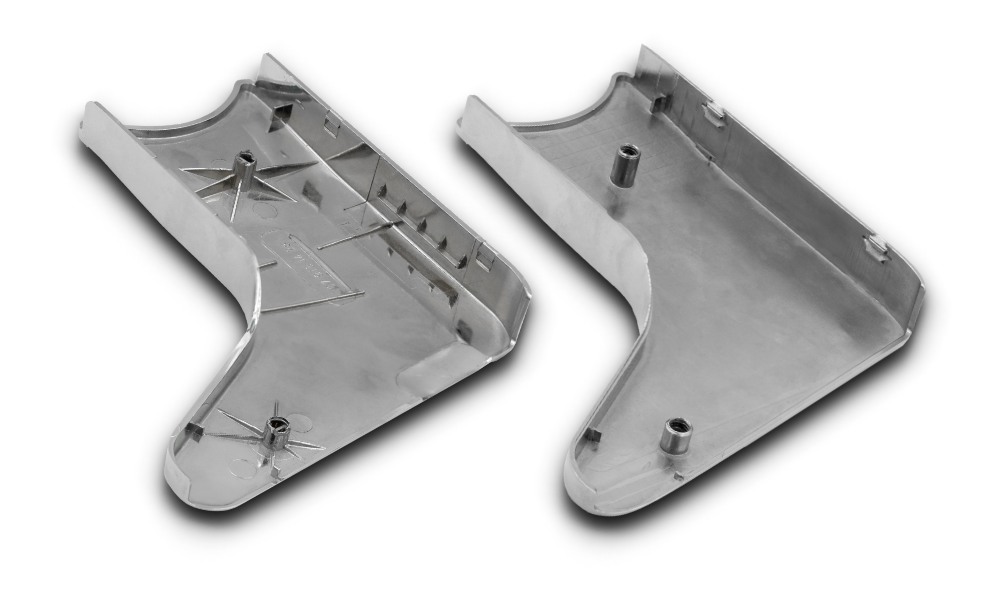

- KDrive housing, turbine parts,

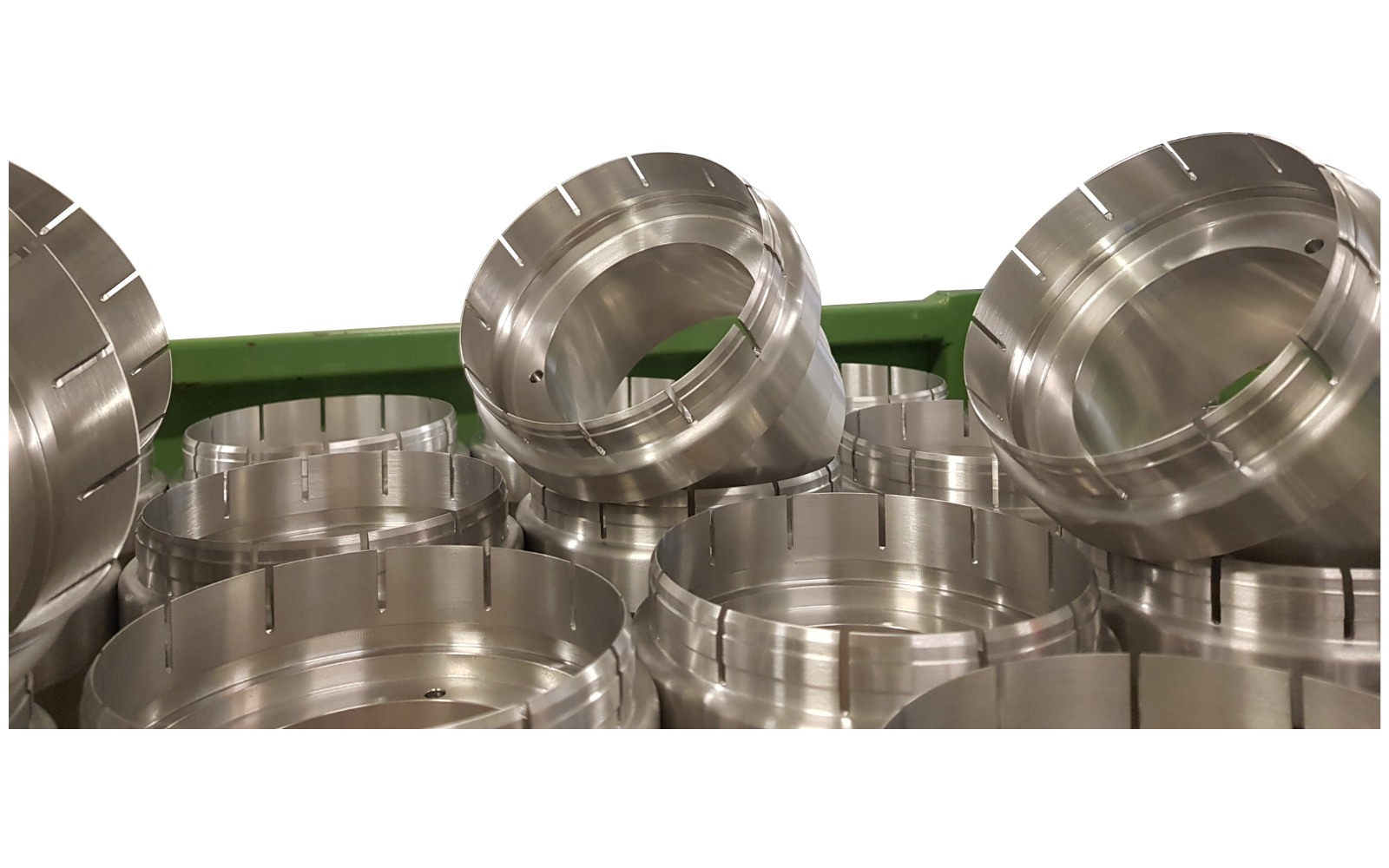

- KControl discs,

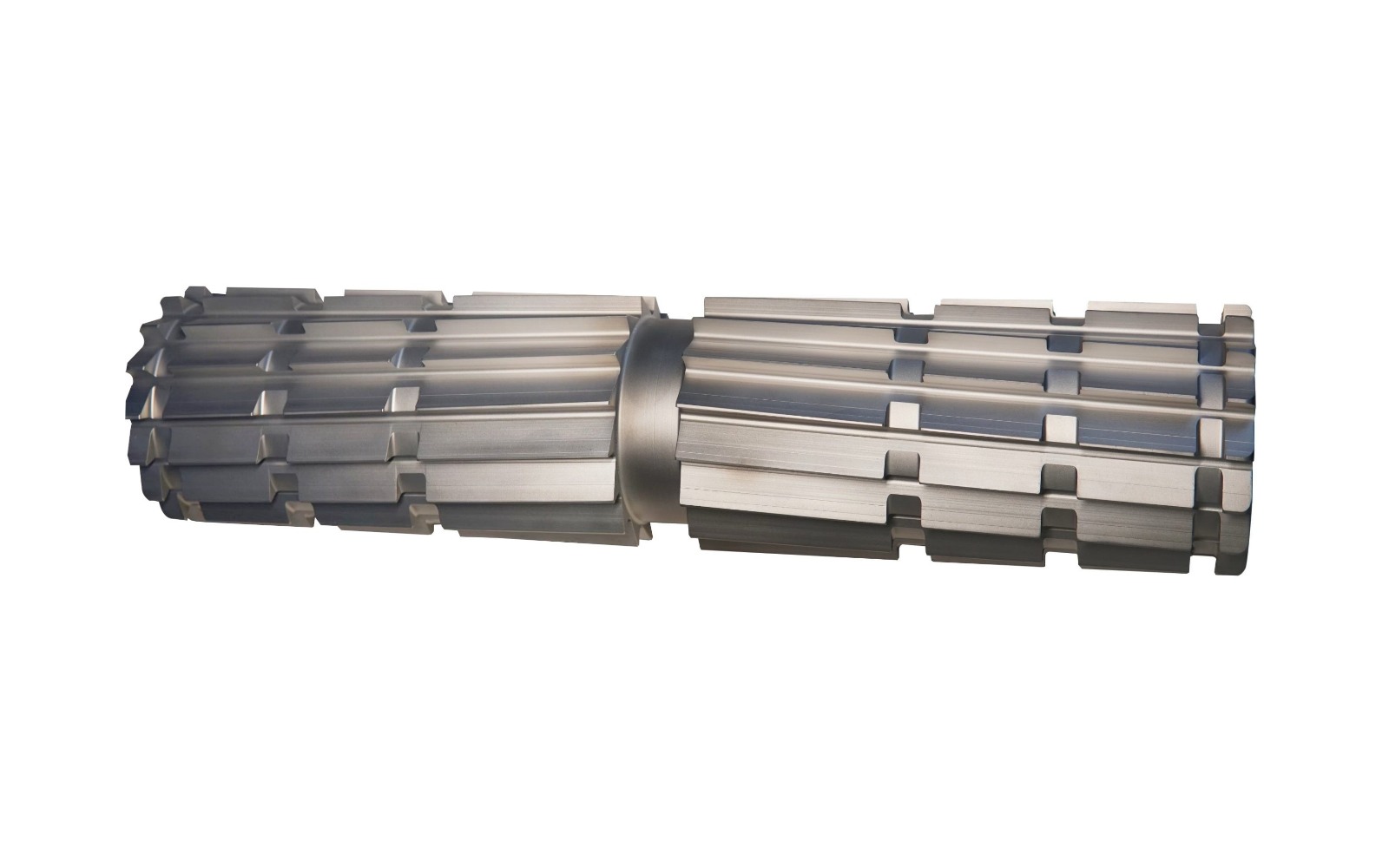

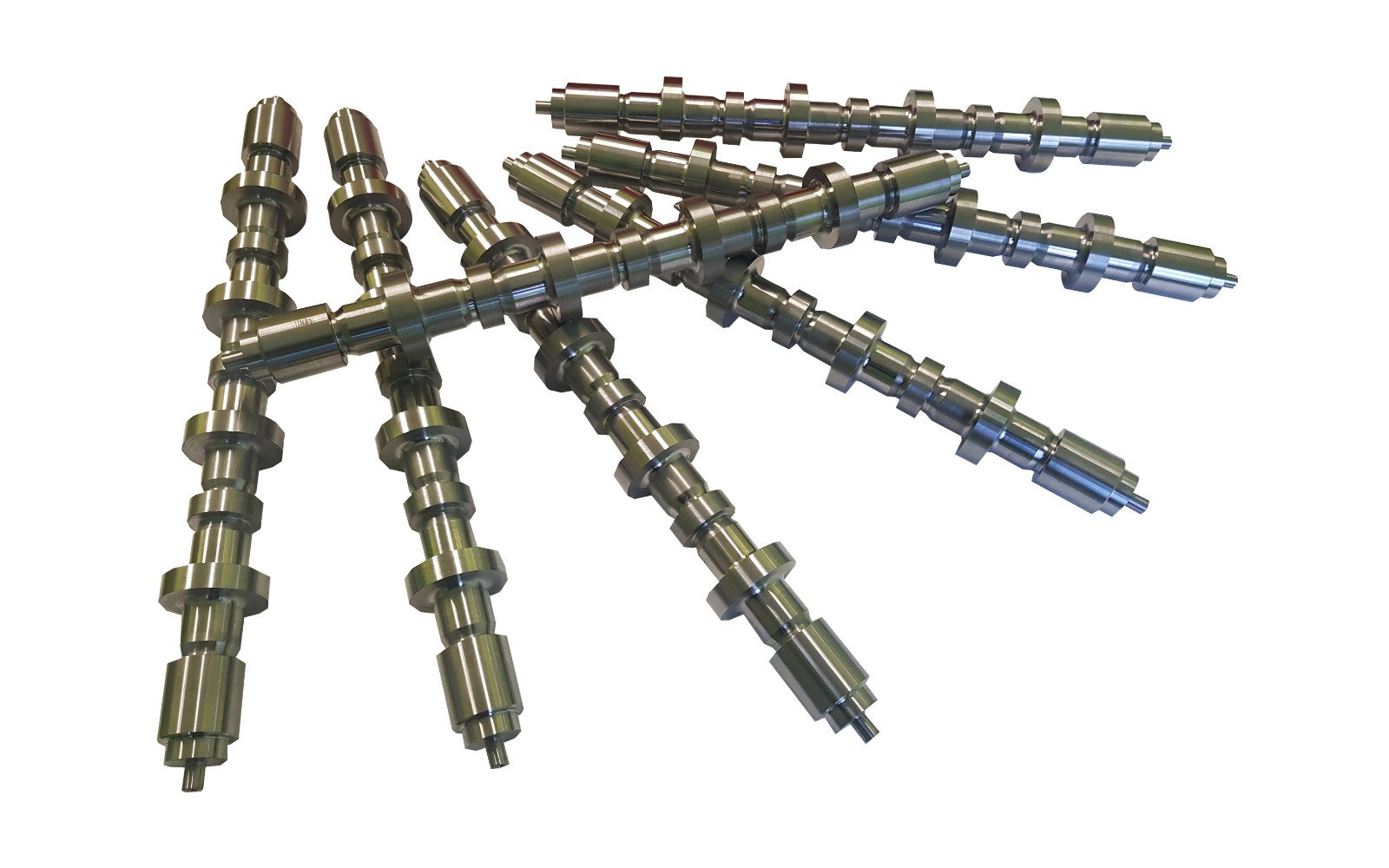

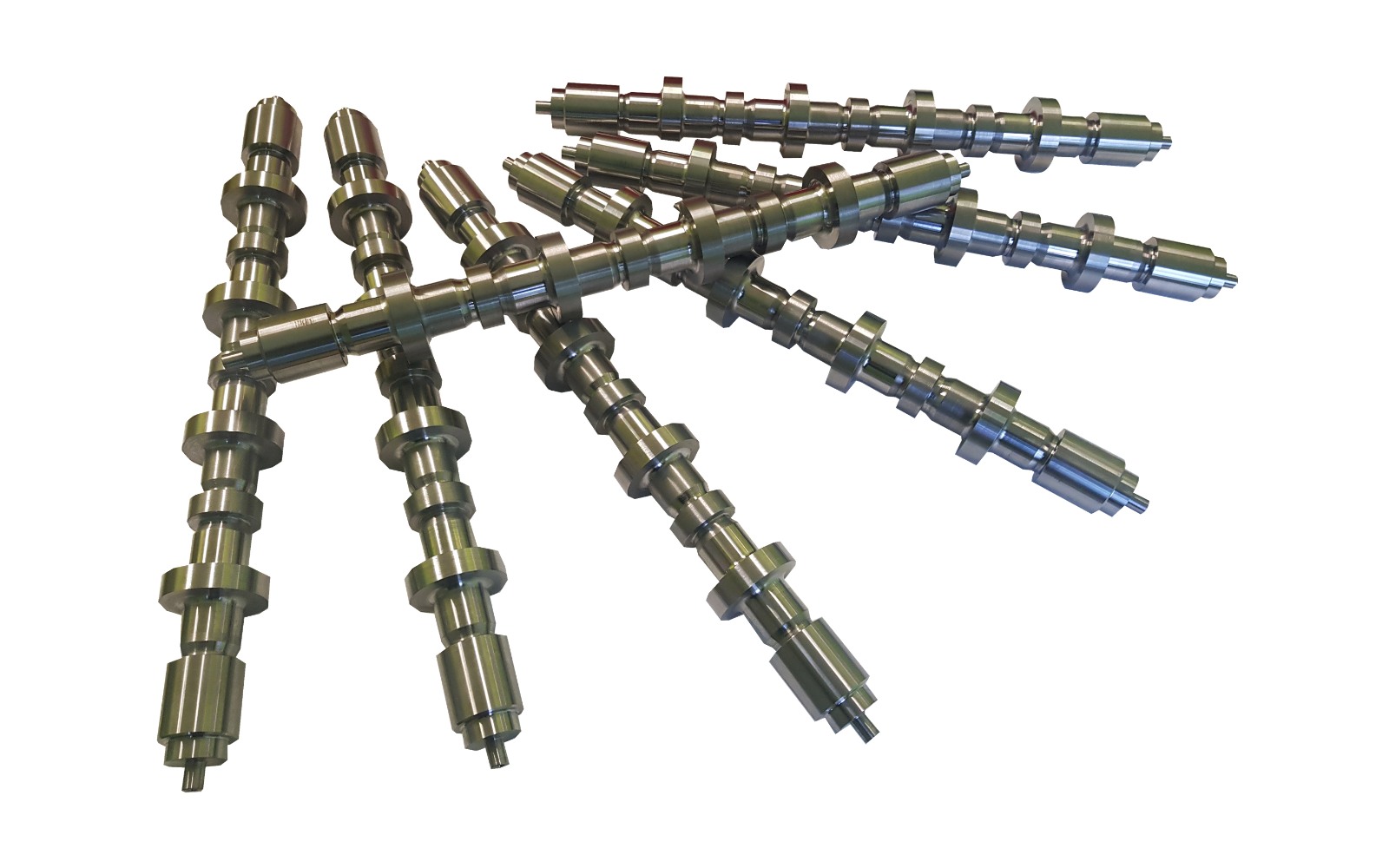

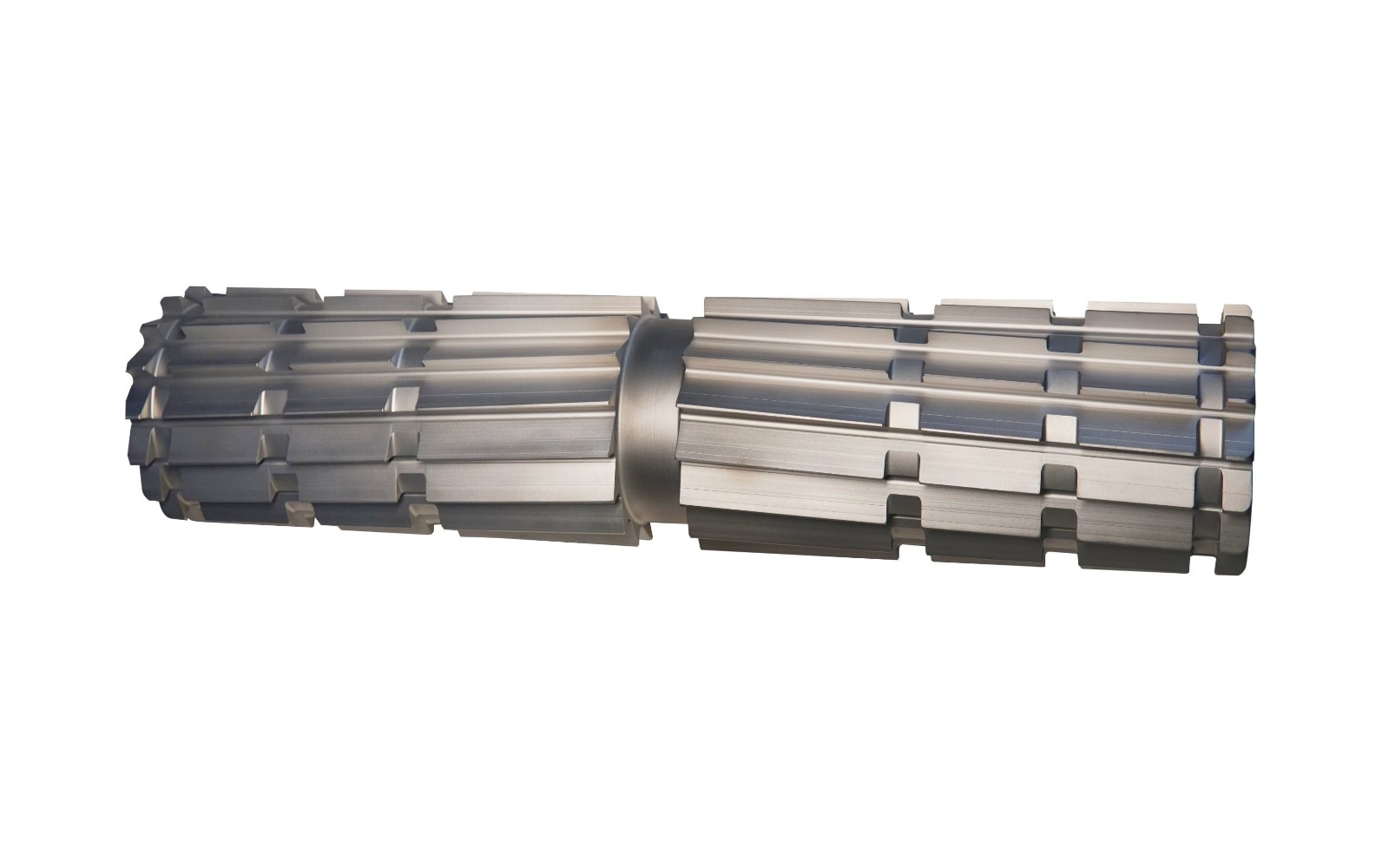

- KCurve shafts,

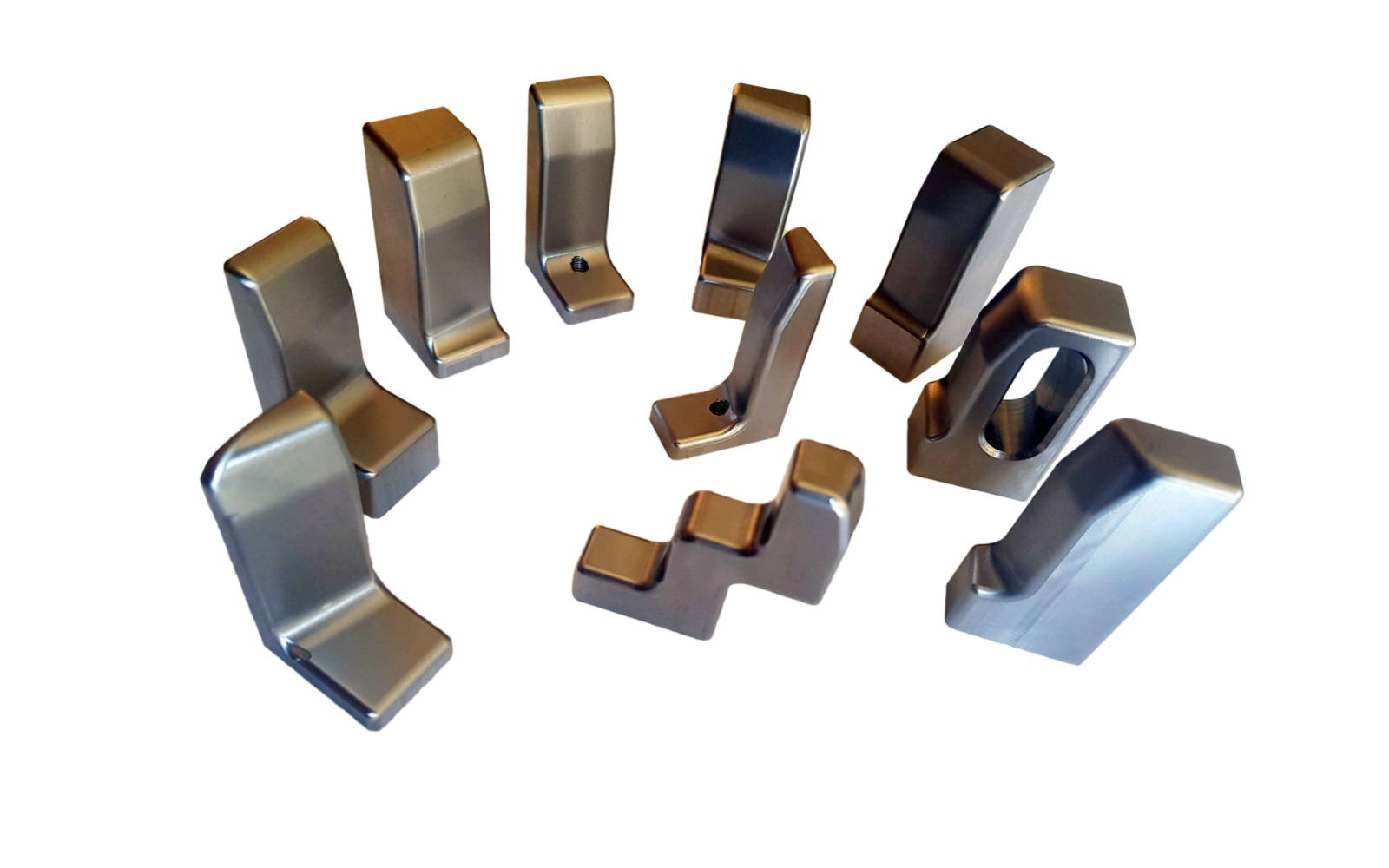

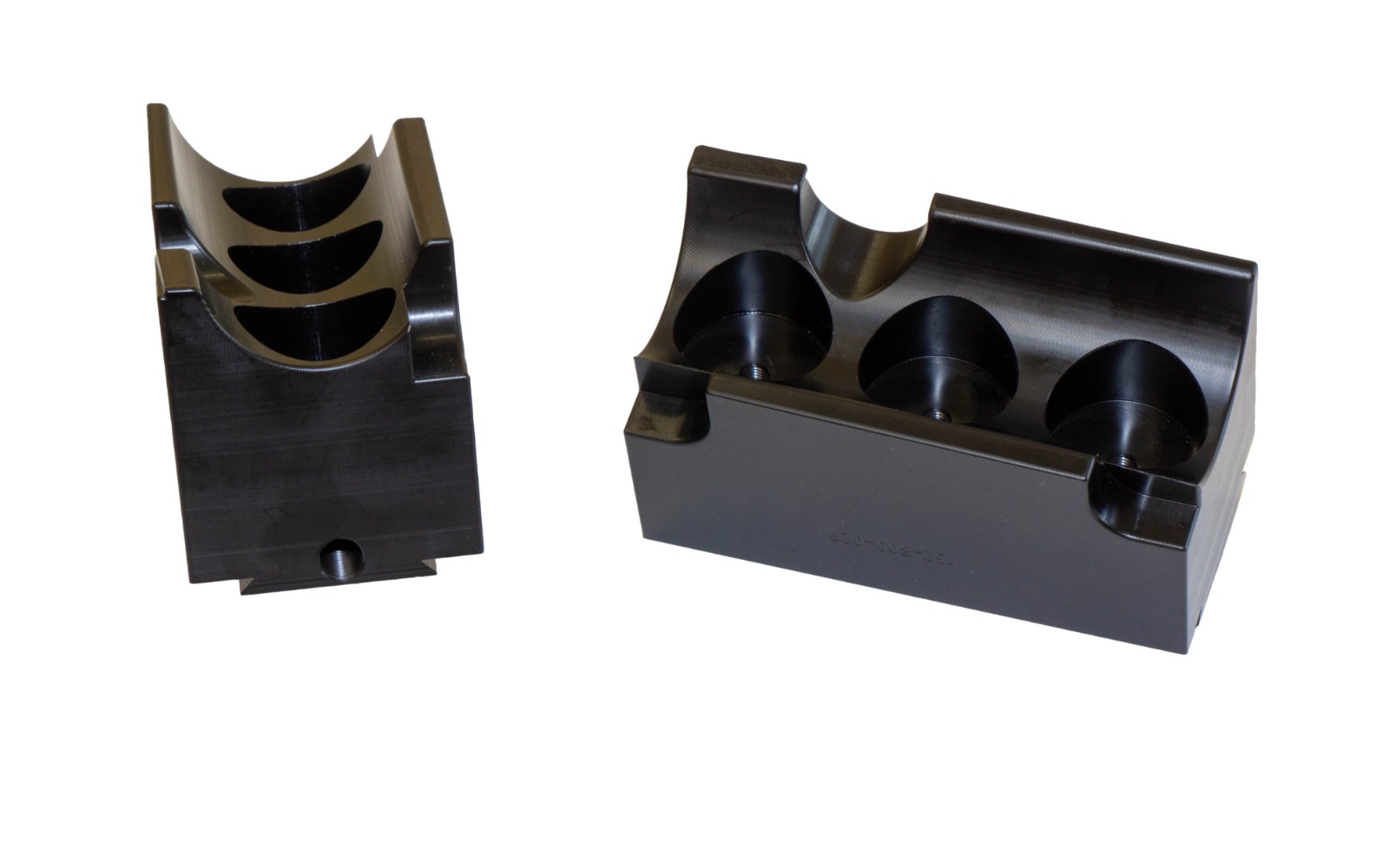

- KForm inserts/ tool inserts,

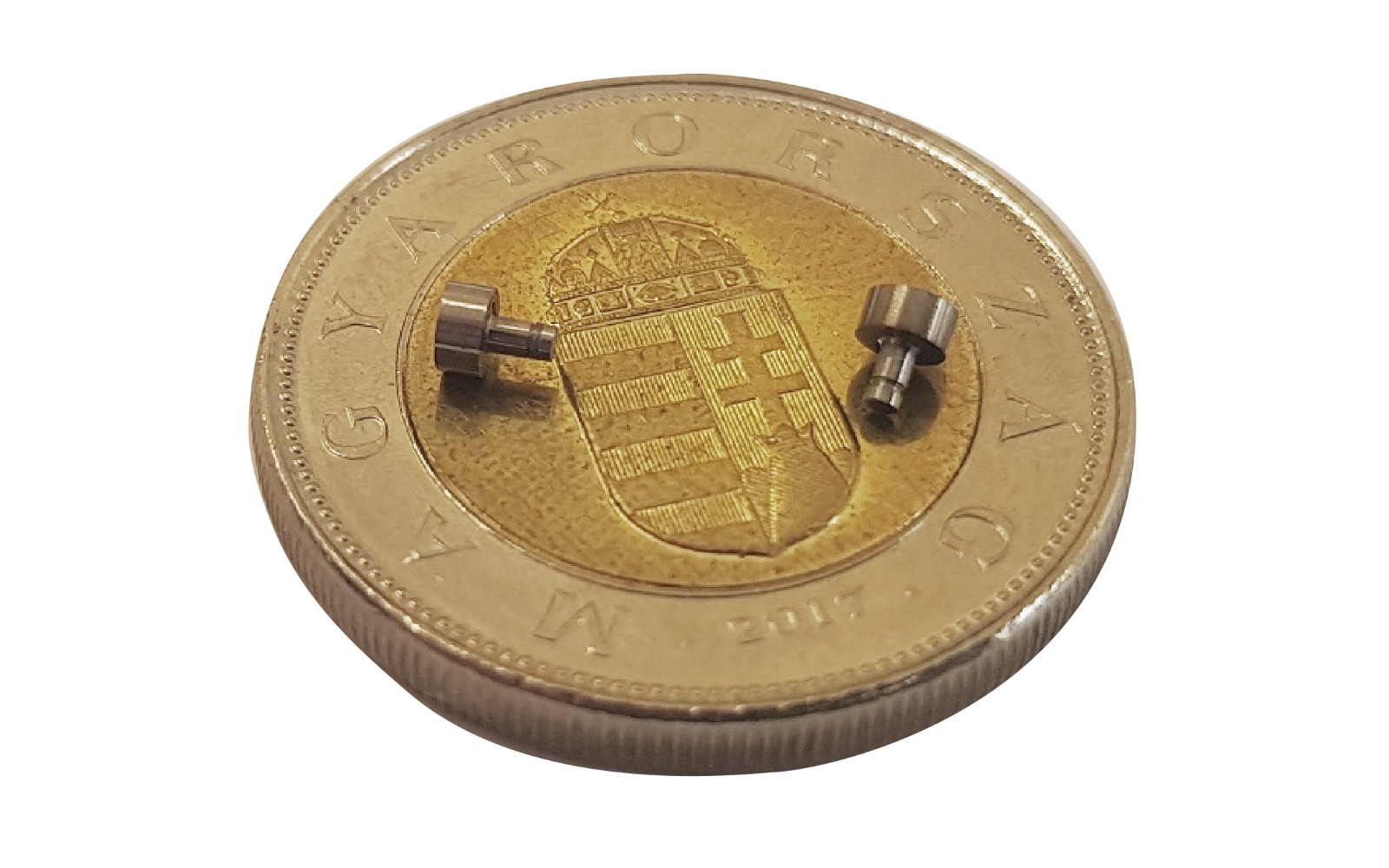

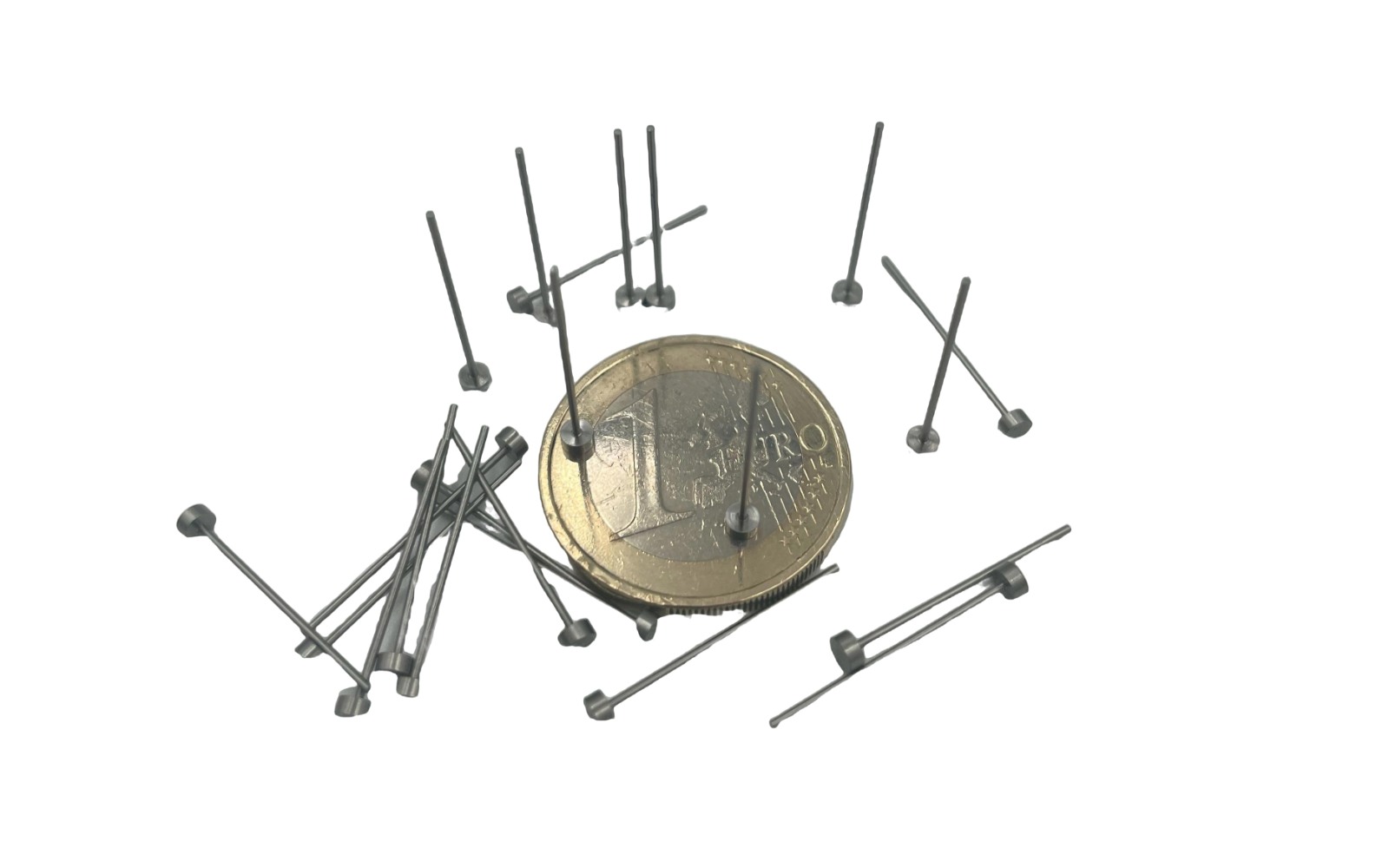

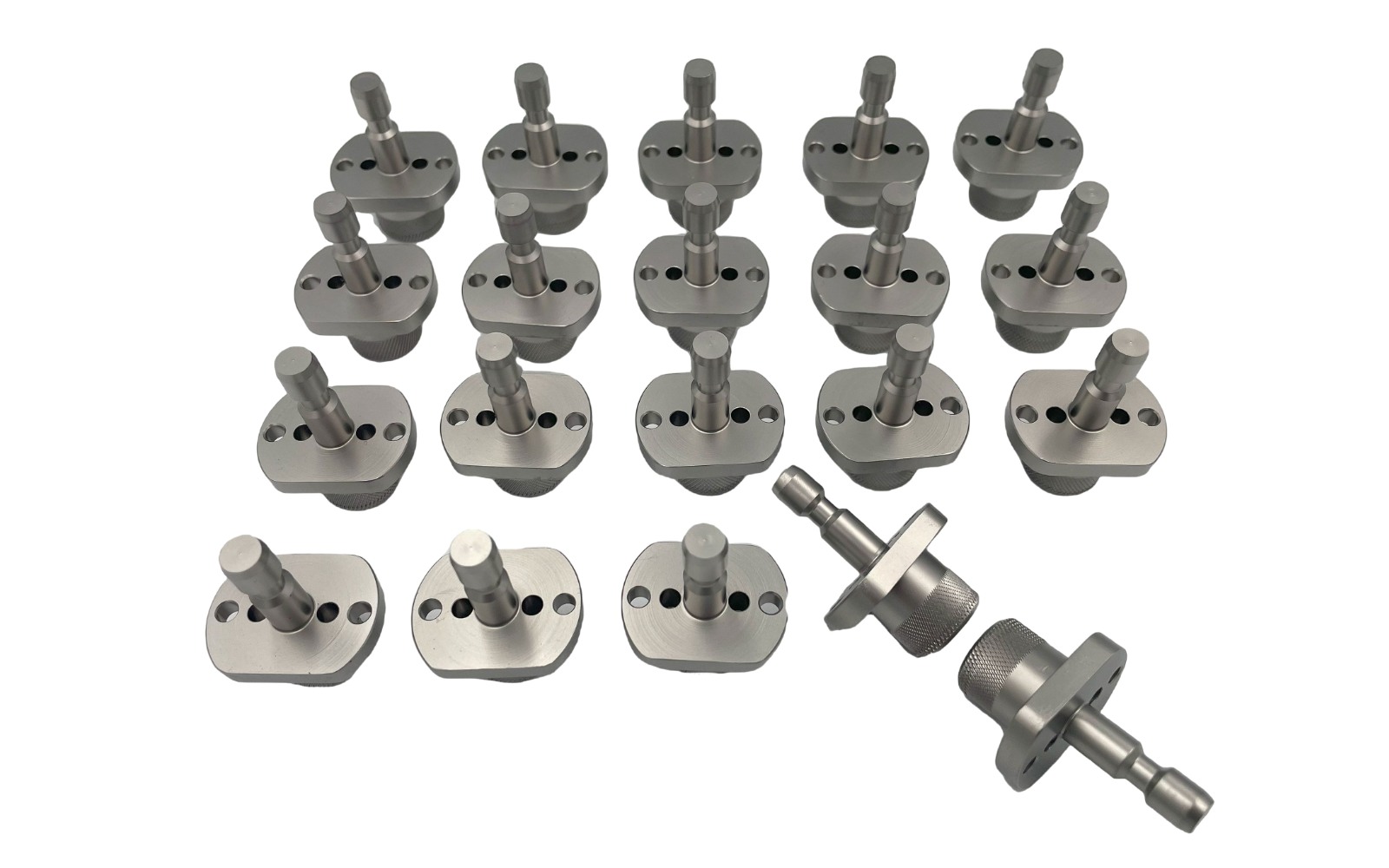

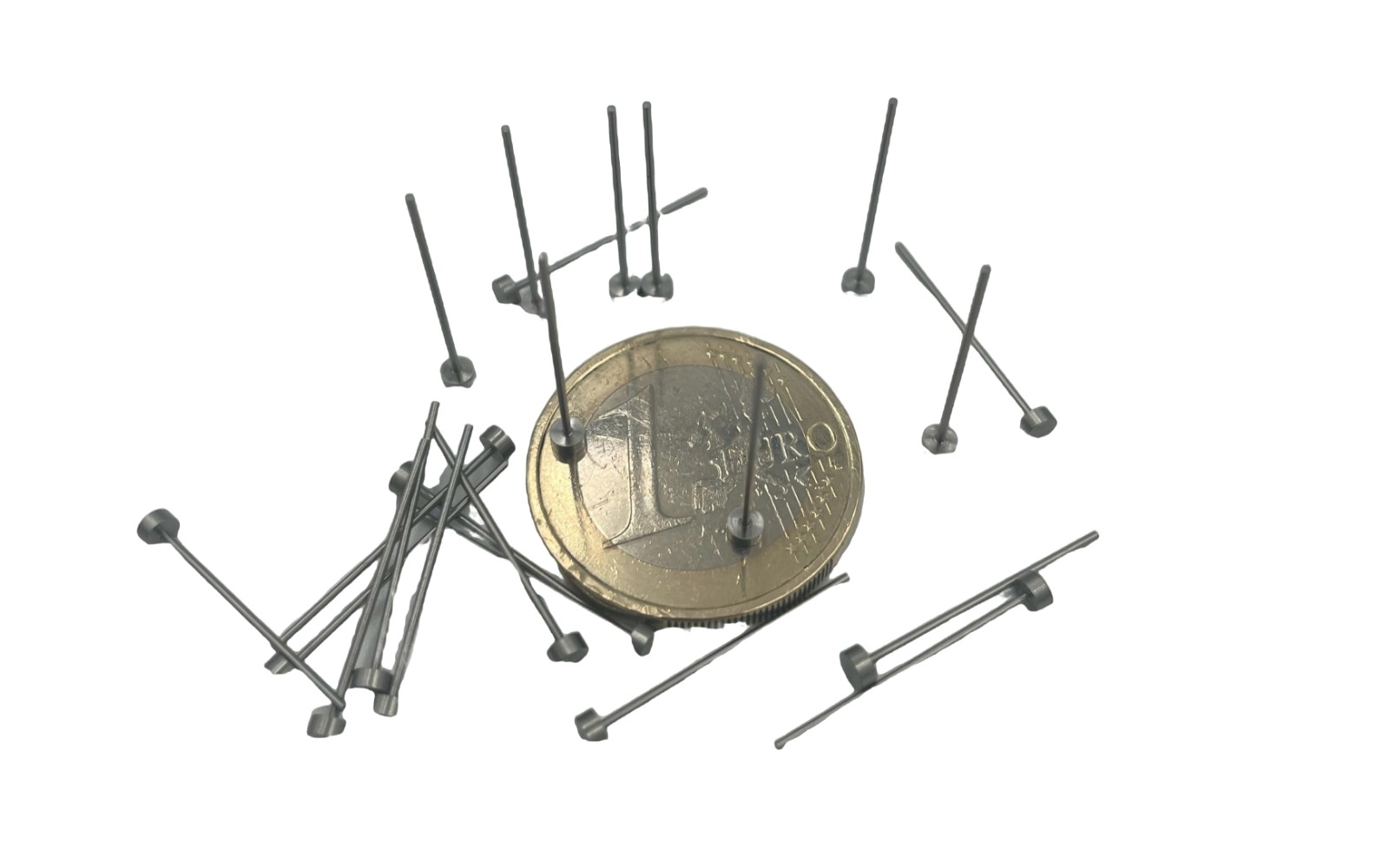

- KCostum ejectors, costum flat ejectors, costum ejector sleeves,

- KCostum bore makers, individual core pins,

- KIndividual punching spikes, individual punching bushings, individual pulling spikes,

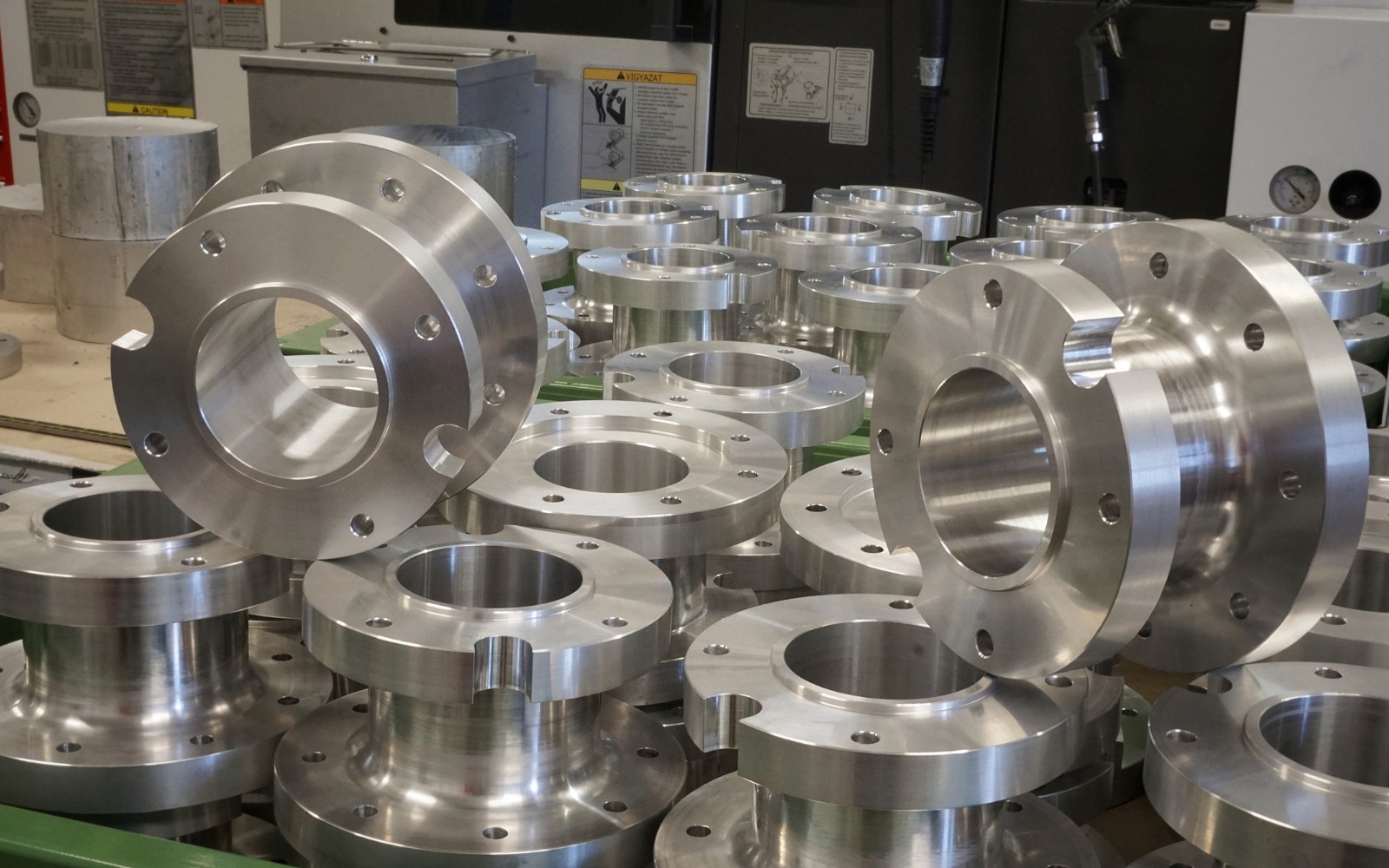

- KParts of small and medium series,

- KMiniature elements,

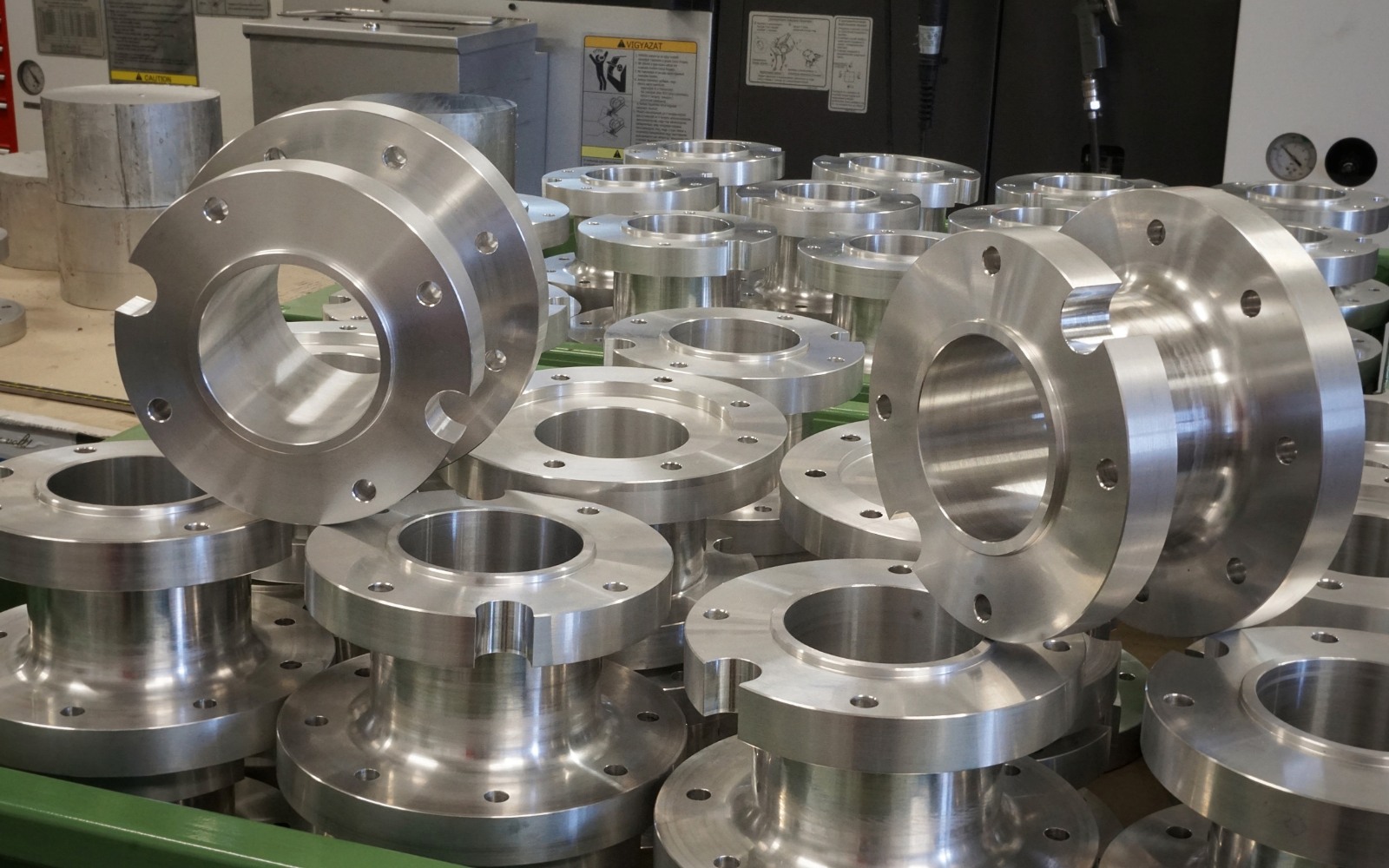

- KTurned parts.

We deliver everything from a single point – from sample making up to series production, from simple workpieces up to complex assembled parts!

Efficiency and support

Our dynamic team responds quickly to you proposal requests. We perform the urgent, express assignments with the same reliability and accurate deadlines, as the framework orders.

We guarantee the highest quality based on innovative CAD/CAM and engineering solutions, modern CNC technology (indexed 5-axis milling and simultaneous 5 axis milling). We are able to receive the technical documentation in the following formats: SolidEdge, EdgeCam, AutoCad, Parasolid, STEP and IGES, …etc.

We always keep in mind long term co-operation. Test our quality and our delivery reliability!

The Quality

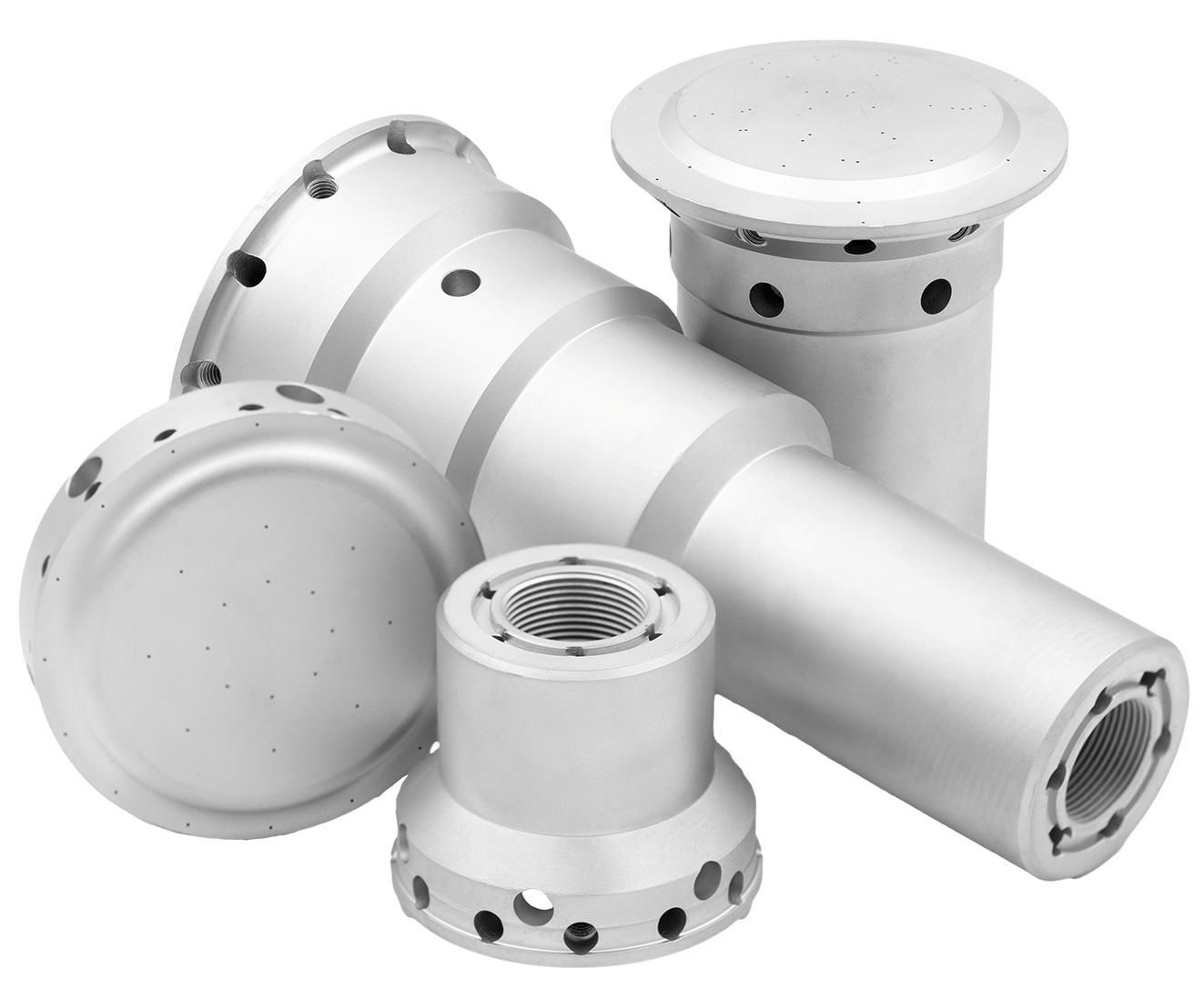

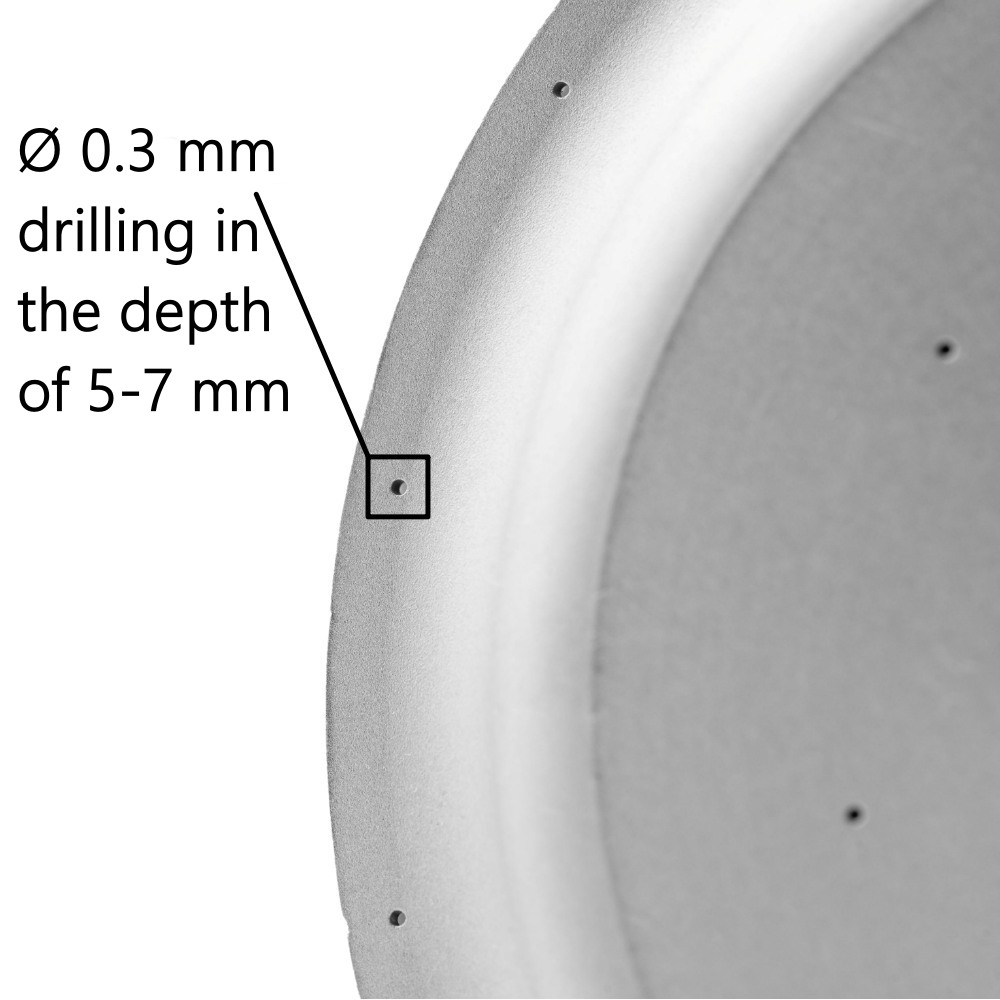

Quality assurance with an innovative measurement technology.

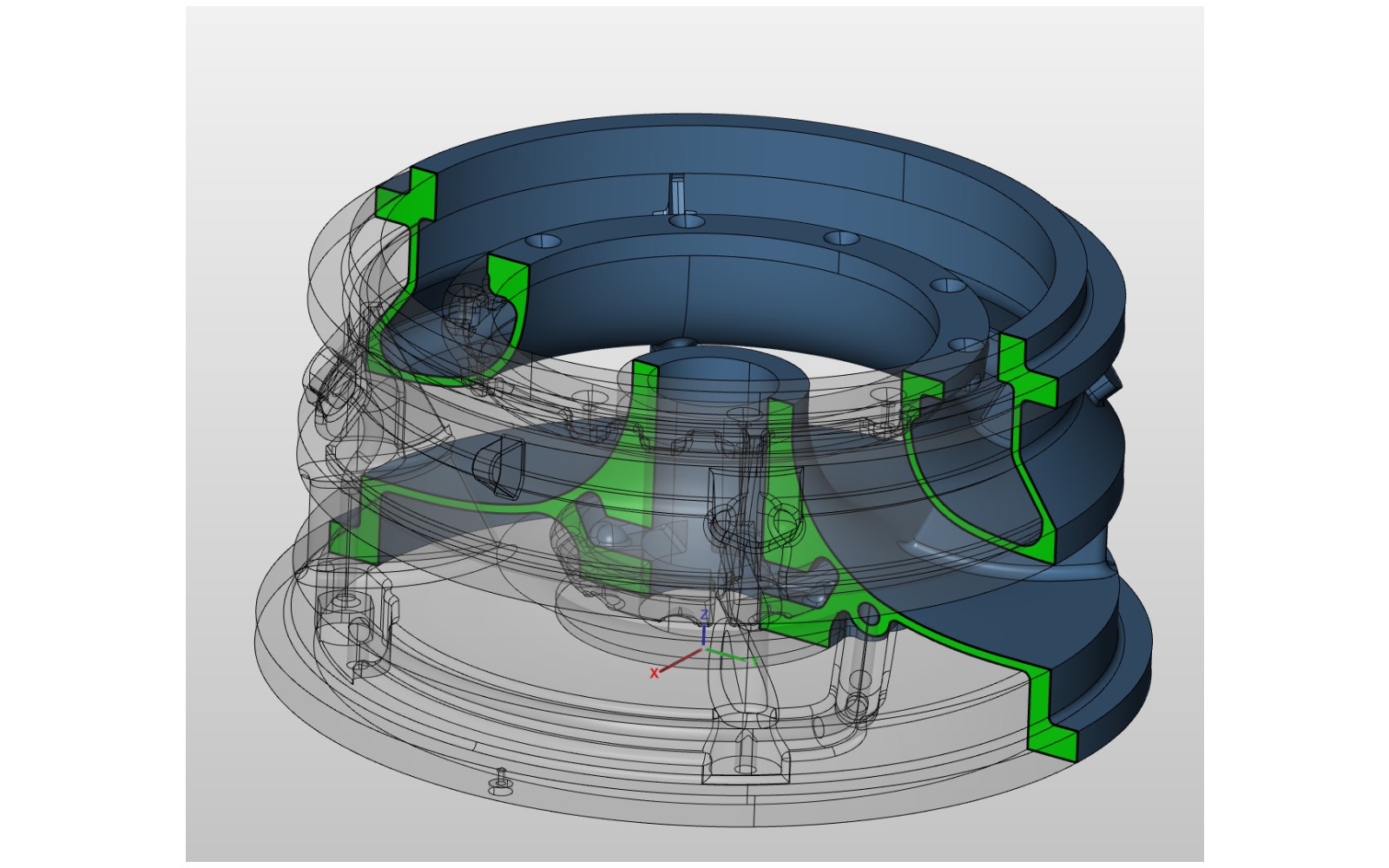

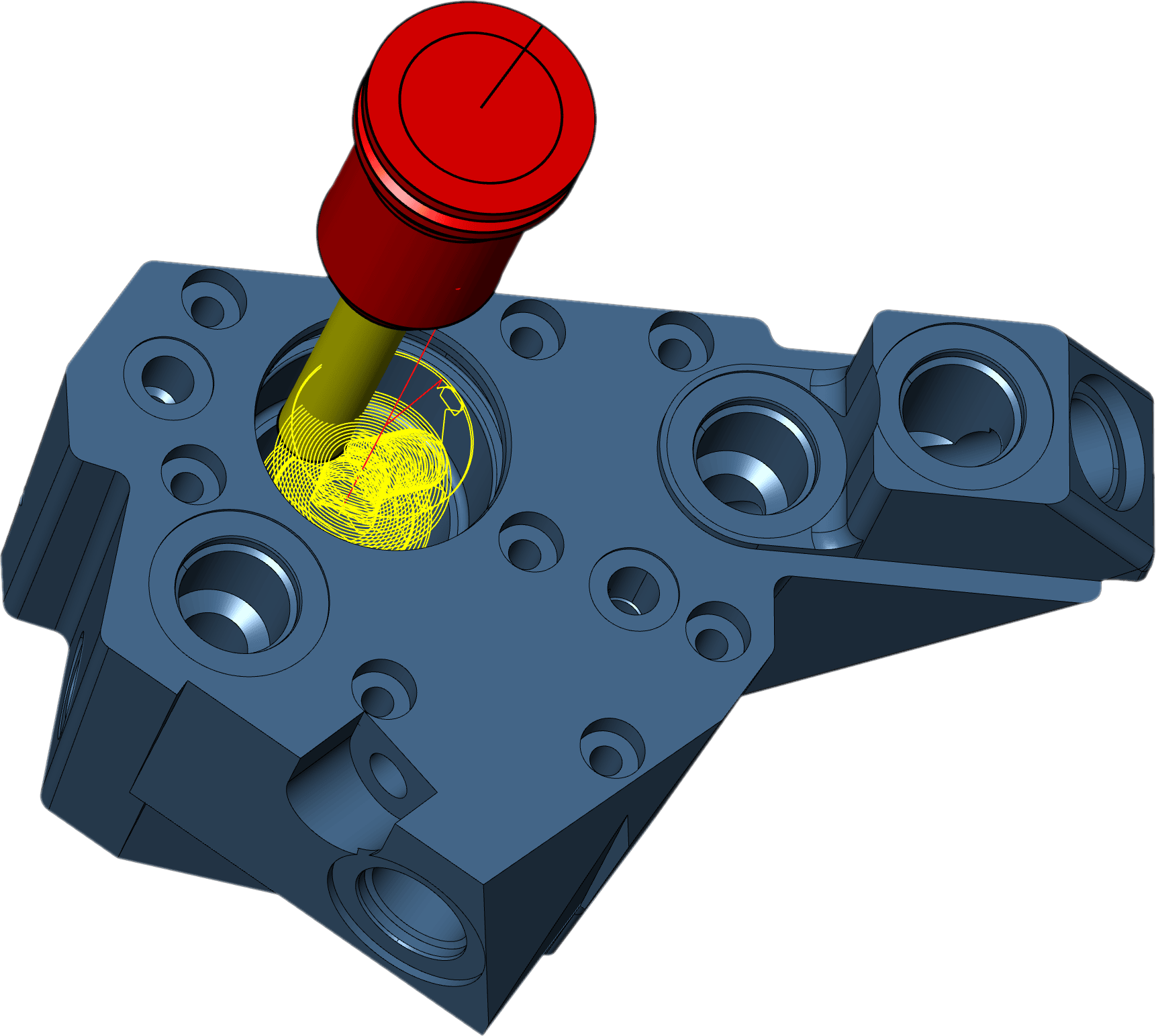

hyperMILL® PROBING We implement our measurements directly on the machine tool!

Carrying out the measurements during the process makes it possible to recognise the manufacturing defects especially in the case of NC machining at an early time, and to react on them immediately. With this we shorten the lead time and at the same time we ensure the quality of the parts. 3D point measurement is a special feature, with the aid of which we may touch surfaces of arbitrary forms, and we may carry out this measurement even on our simultaneous 5-axis machining machines.

Its advantages are the following:

- Improved quality and process control

- Shorter lead time

- Accelerated quality assuring process

- Enhanced safety and less scrap

We work according to quality management systems MSZ EN ISO 9001:2015 and MSZ EN ISO 14001:2015.

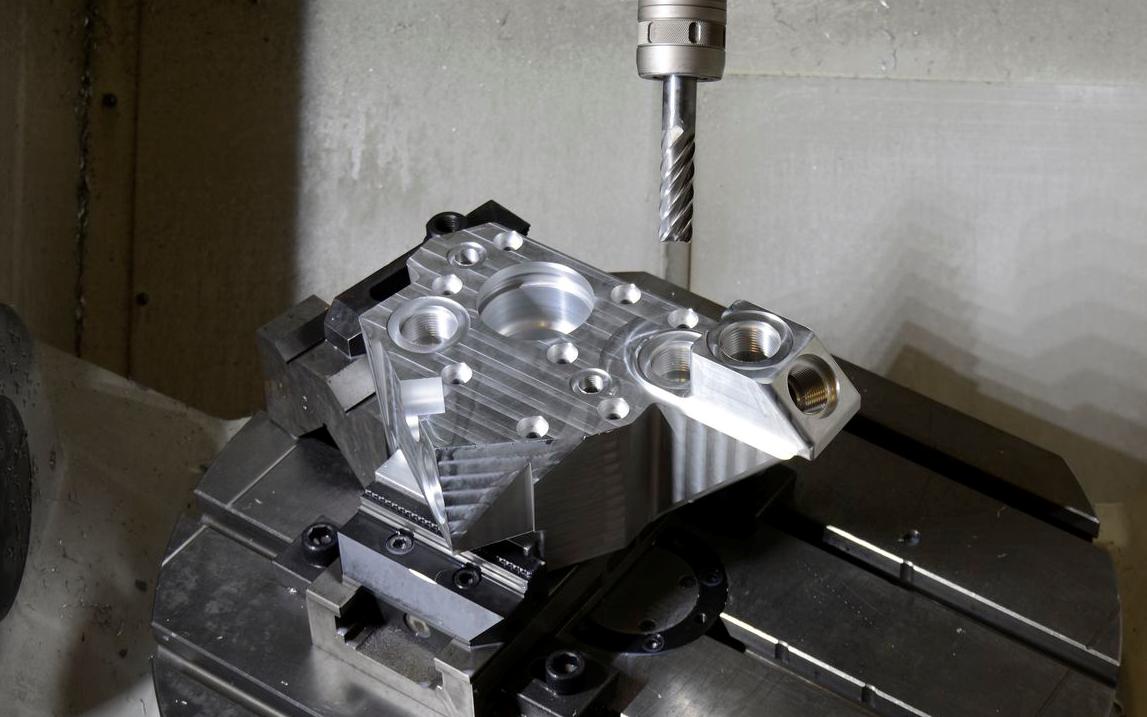

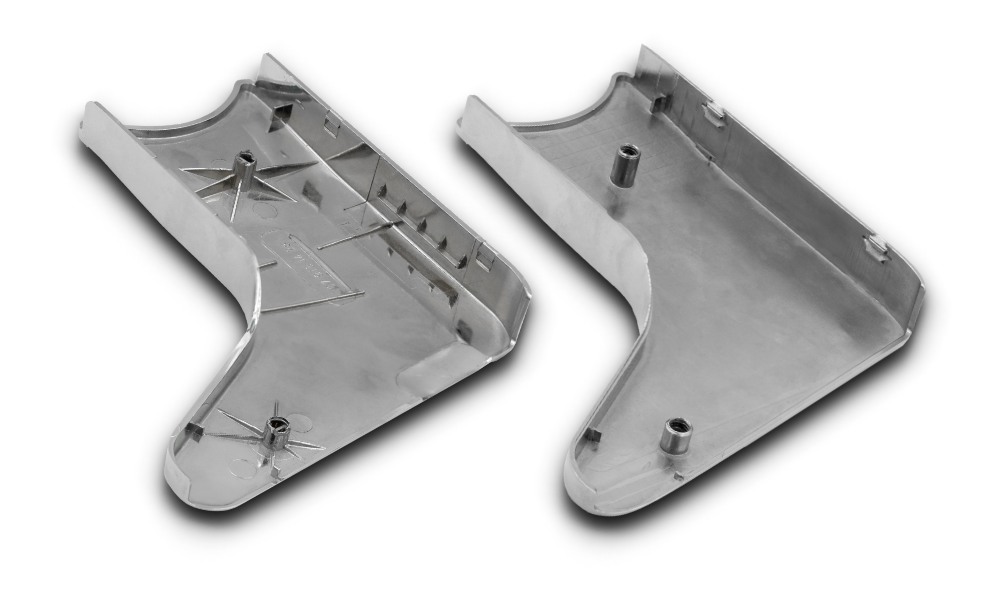

Indexed 5-axis milling

We exploit the following advantages by using the indexed 5-axis milling of complex workpieces: shorter machining times, better surface quality, higher manufacturing accuracy, with in most of the case 2 or only 1 clamping.

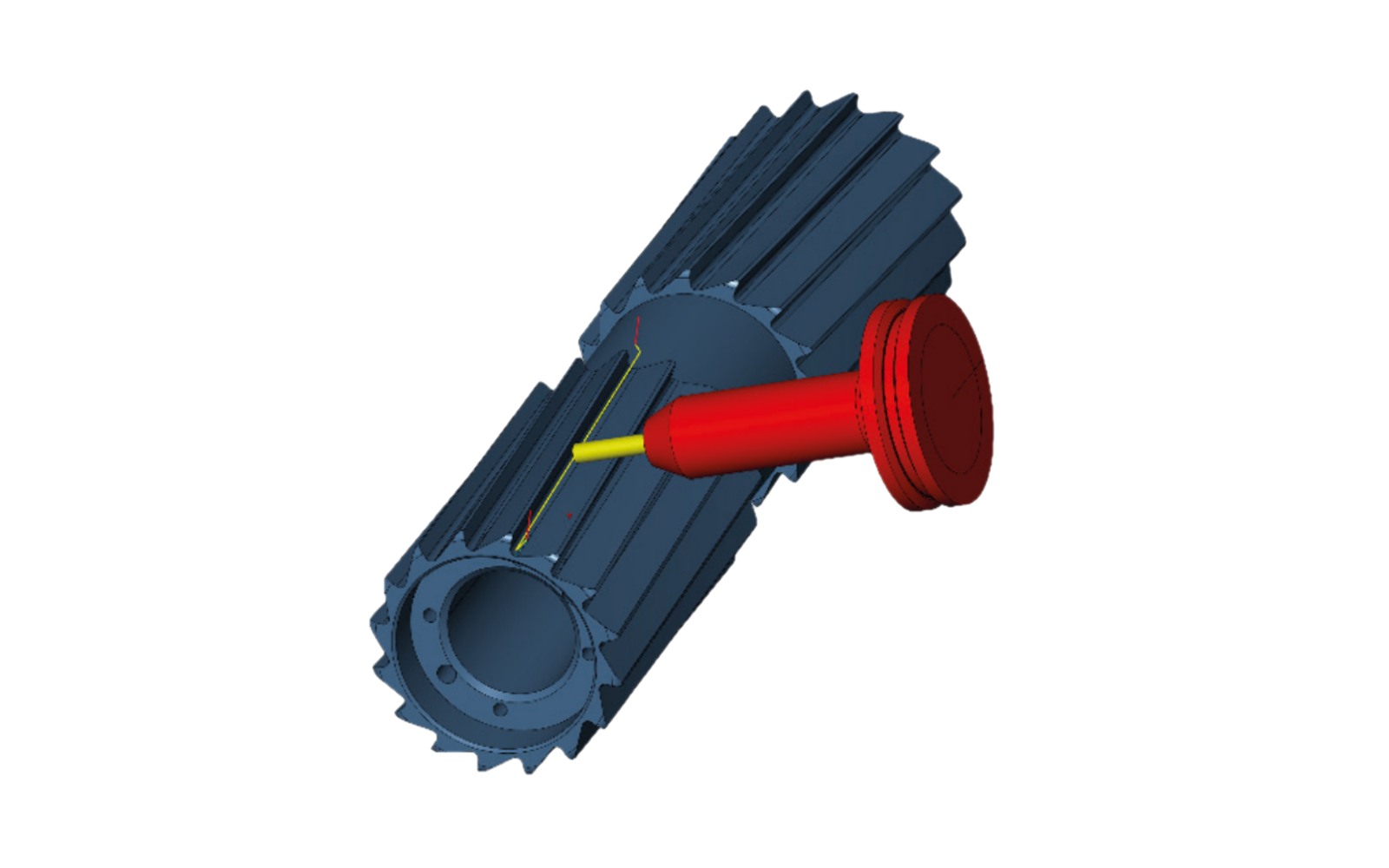

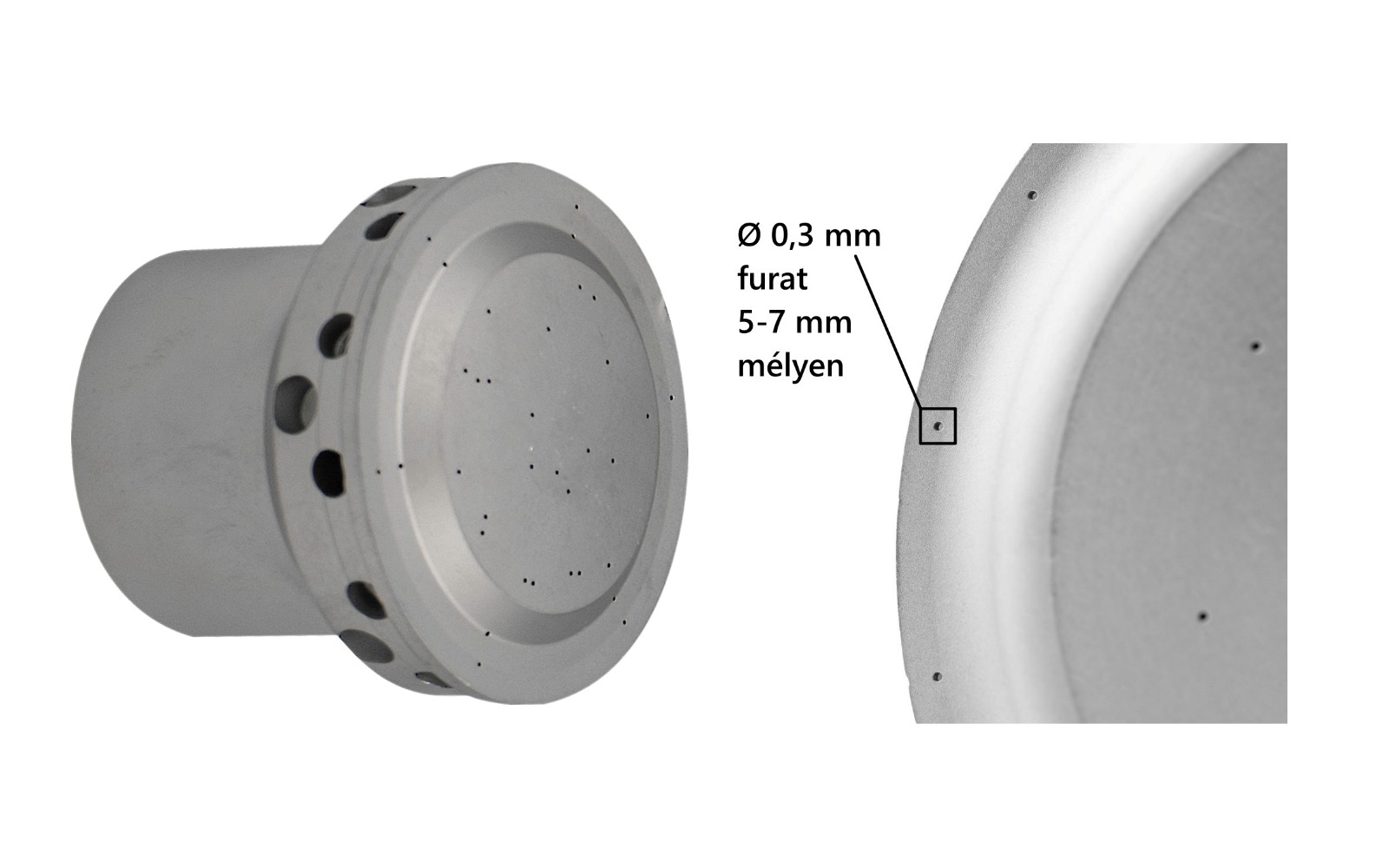

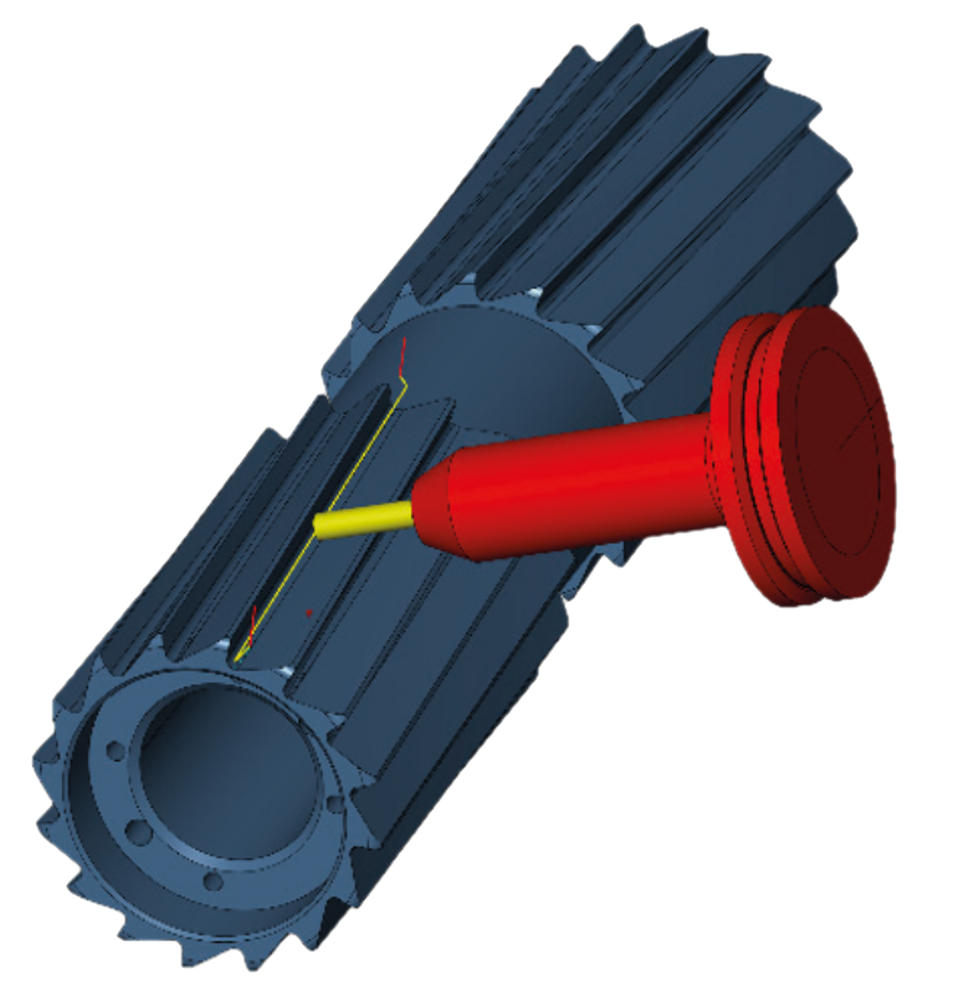

Simultaneous 5-axis milling

It is possible to prepare very complex parts with the traditional cutting technology only with a very high time investment, or not at all. In these cases we solve our manufacturing tasks with simultaneous 5-axis milling, in which case the advantages that are listed in the case of indexed 5-axis milling do also exist.

Our CAD/CAM System

Special CAM-systems are needed for both indexed 5-axis and simultaneous 5-axis milling strategies, which CAM-systems use CAD-models for determining safely and in advance the movement of the machine. We prefer HyperMILL in our daily work.

Reverse Engineering

If you need an old part, spare part that is already not available on the market and there is no technical documentation (drawing or 3D-model) about it, or as a consequence of use, transformation or repair the part already does not correspond to the technical documentation, then we can scan and digitize it, and on the basis of the captured set of points we can generate a 3D-model and then with the aid of the CAM-system we can remanufacture it for you.

Frequent areas of application: archiving, spare part manufacturing, dentistry, medical technology, model making, Oldtimer items, remanufacturing of tools.

Technologies

- KSimultaneous 5-axis CNC milling (D700 x H450)

- KIndexed 5-axis milling (D700 x H450)

- K3-axis milling (X: 2.500, Y: 700, Z: 710)

- KCNC turning (d350 x L500)

- KWire EDM, block EDM

- KMantle grinding (d250 x L750)

- KPlaning shot blasting

- KPolishing, structuring

- KWelding up to 300 kg

- KCuring

Industry segment supplied by us

- KConstruction and manufacturing of special purpose machines

- KElectronics

- KEnergy sector (drive housing, motor housing, turbine parts, fan housing)

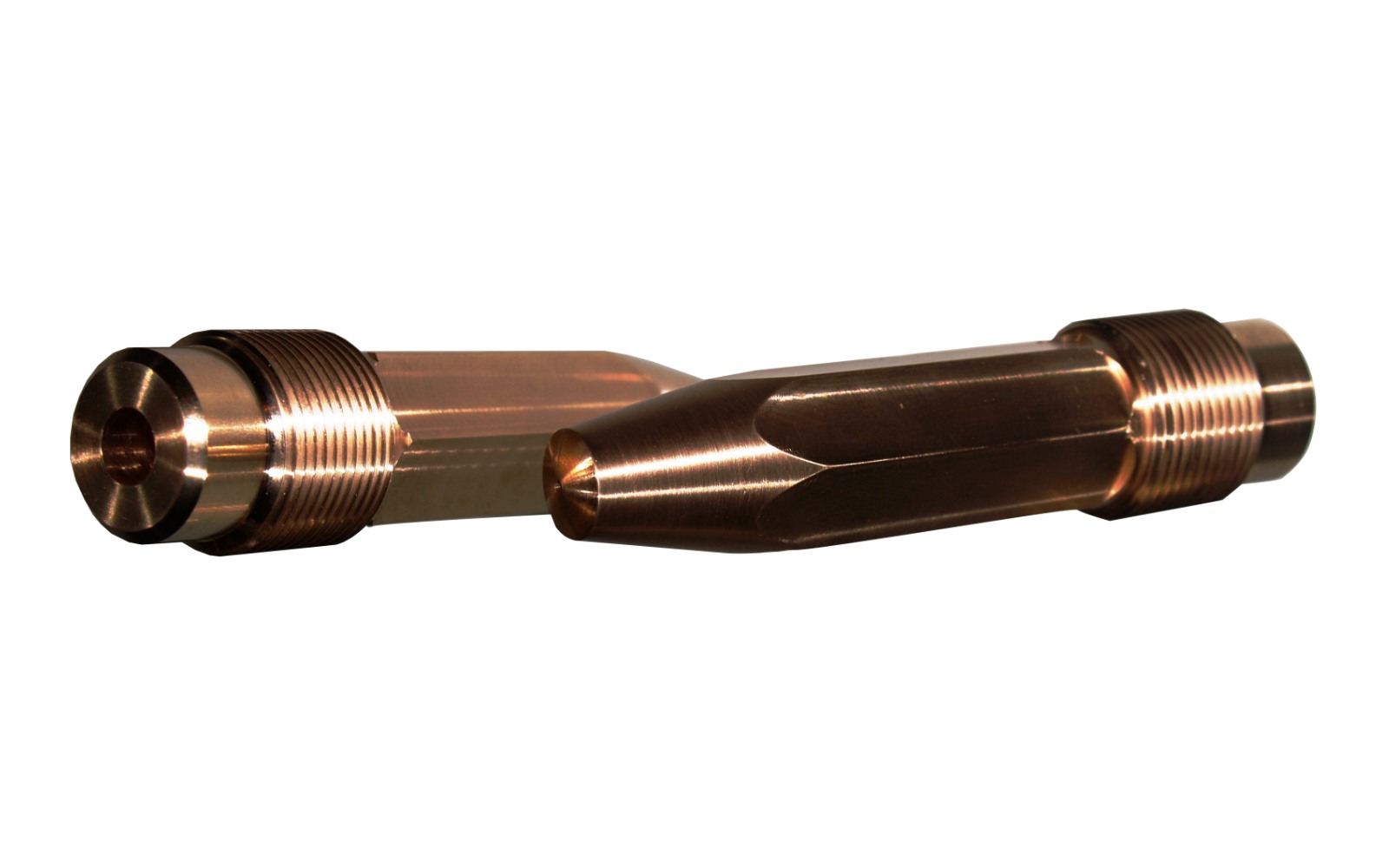

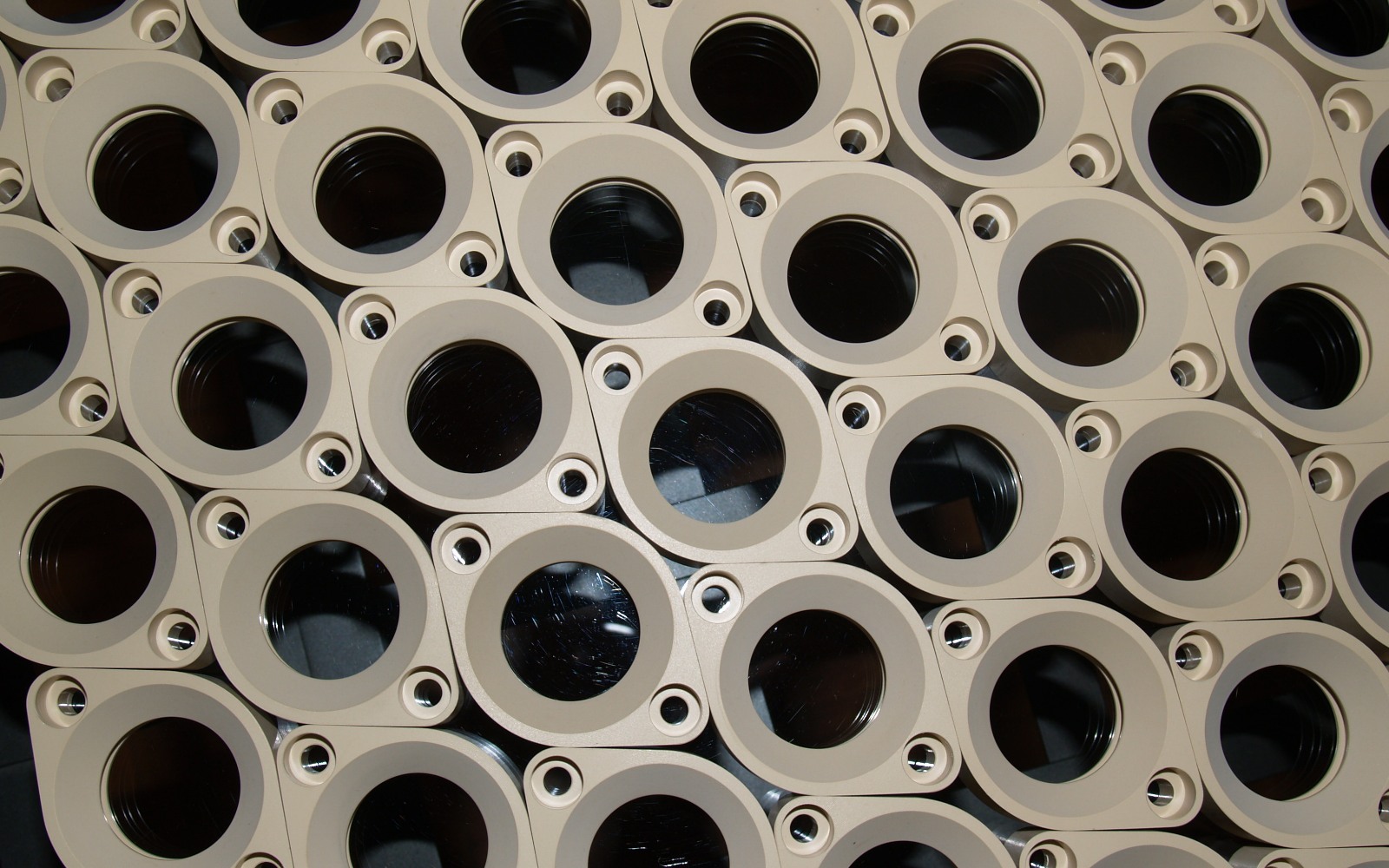

- KFood industry, bottling plants, PET bottles production (neck grippers, gripping cones)

- KArmaments industry

- KVehicle industry

- KPlastic industry, plastic injection moulding

- KModel construction and model manufacturing

- KDie casting

- KOldtimers - Reverse Engineering

- KPrototype manufacturing

- KProduct development

Raw materials, surface treatments

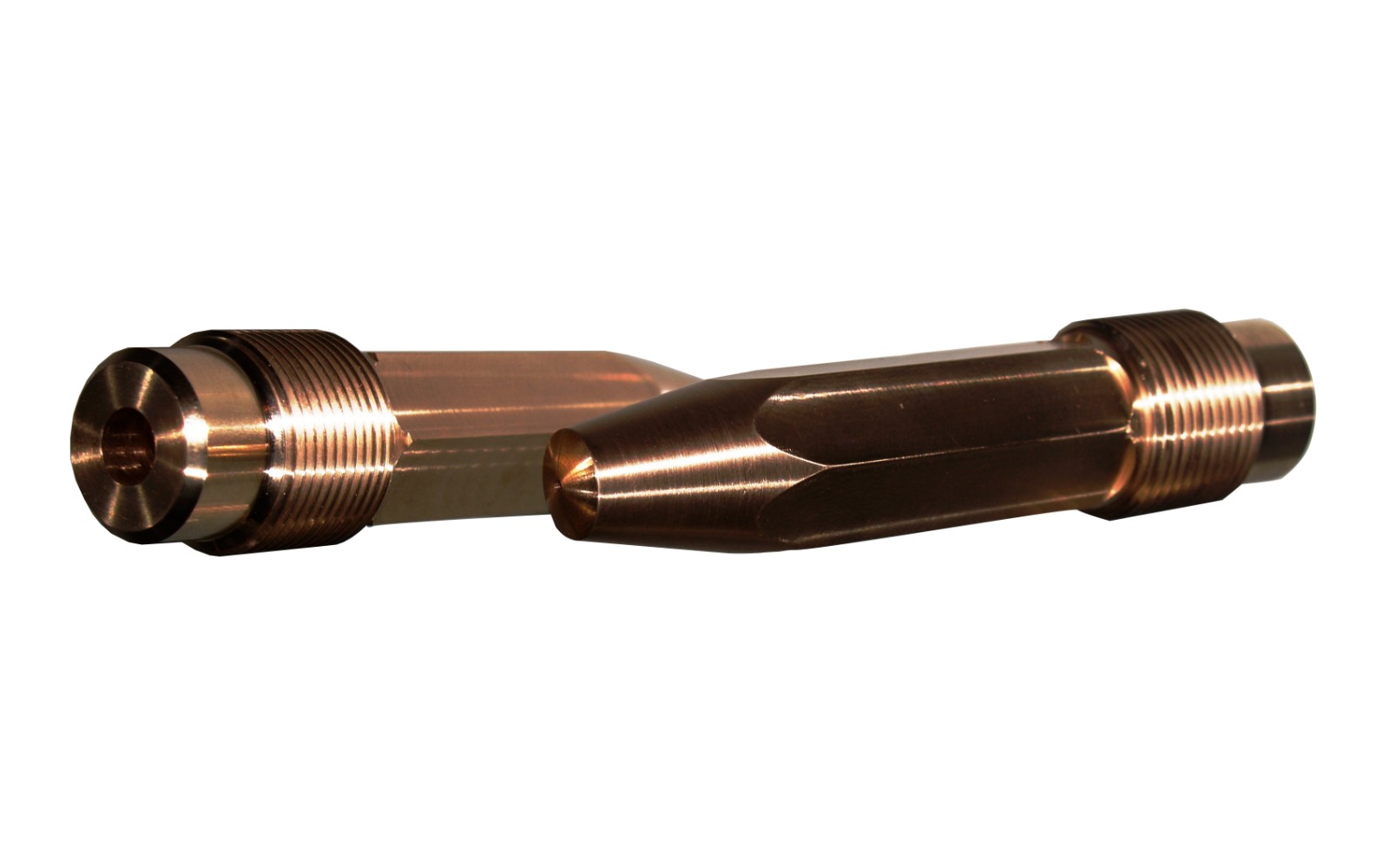

The products we deliver for our customers are made from a very wide variety of excellent quality raw materials, as for example from aluminium and its alloys, noble metals (bronze, brass, red copper and ampcoloy),

hard metal, stainless and acid-resistant steel, hardened steel, high alloy steel (Dievar, Invar, Toolox and Unimax), plastics, technical plastics, tungsten, aluminium alloy, grey casting, spherical graphite iron casting,

precision casting, noble metal casting and steel casting, using the most diverse heat treatments, surface treatments, as for example anodising, painting, galvanising, chroming, as well as TiAlN, or Cr2N coating.

We are able to present our product assortment manufactured by us only partially due to our client confidentiality obligations.