Precision Manufacturing

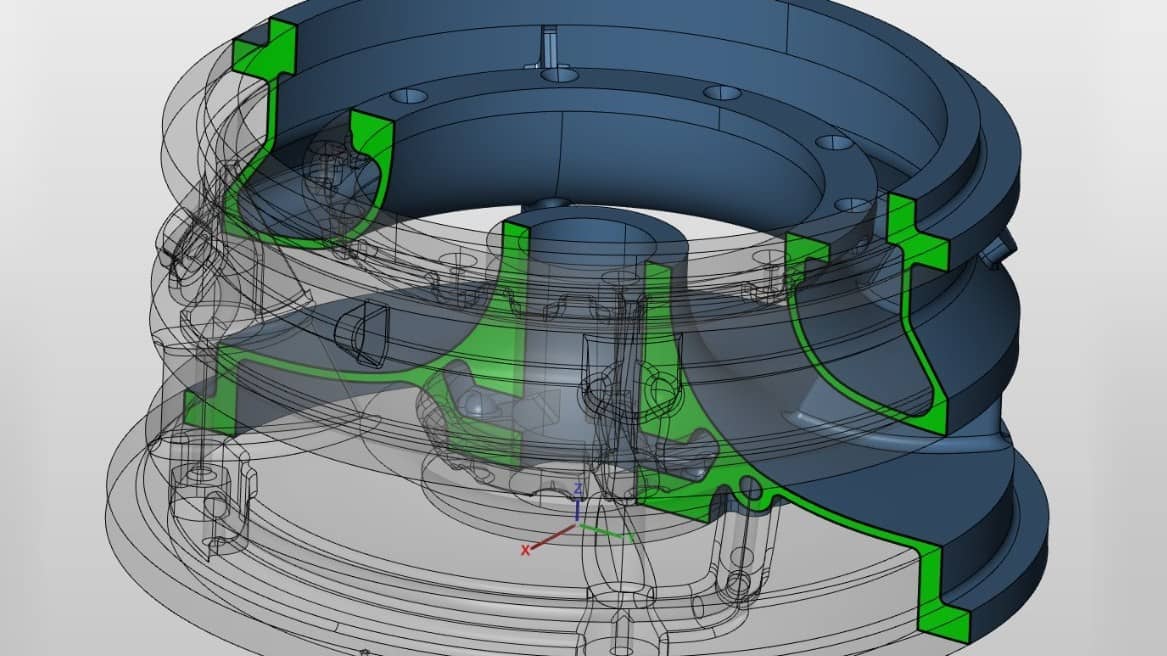

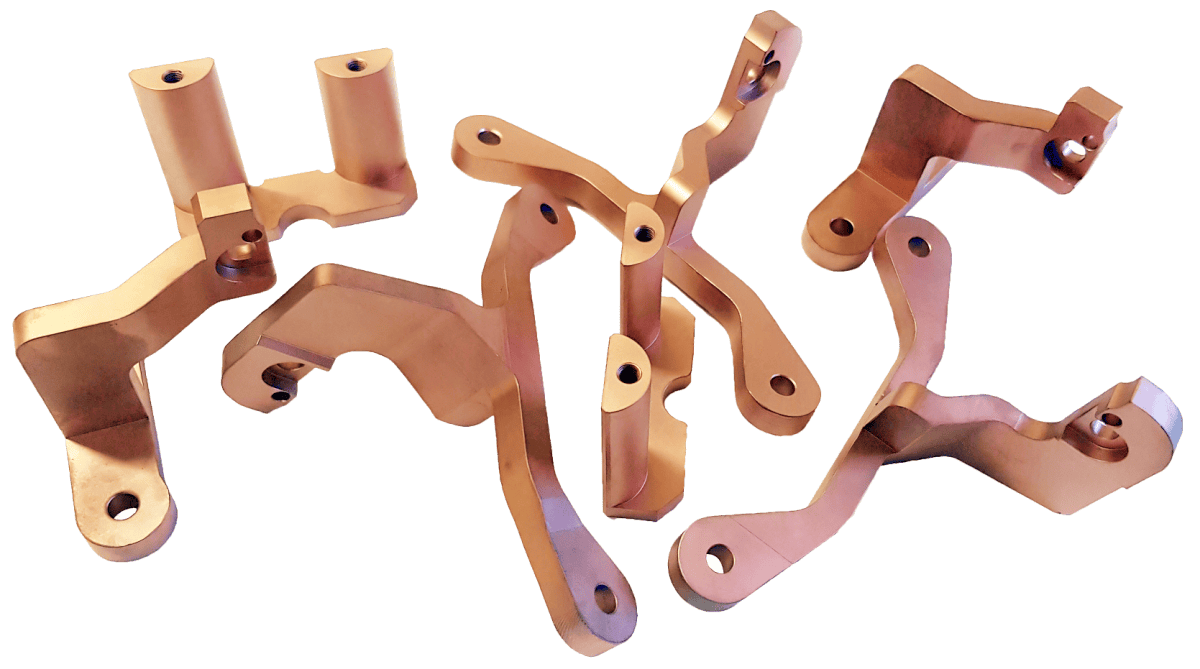

With our close to 20 years of engineering and precision manufacturing experience we are an efficient and reliable partner in the field of manufacturing tool parts, tool inserts, sample items, prototypes, replacement and spare parts of complex geometries, produced with 5-axis simultaneous milling, starting with miniature items through control discs up to drive houses.

Cleaning, Maintenance

With the aid of the innovative Cleantower Optisystem ® technology we clean efficiently heat exchangers, heating circuits and entire water systems. We provide active support for the preventive maintenance of this equipment, for increasing their efficiency and their lifetime.

Sale

In addition to the standard tool portfolio, we serve our clients with products of clearly unique implementation: precision sheets, ejectors, bore makers, punchers, plastic industrial lubricating, conserving, cleaning agents, quick couplers, gas springs, press springs, guide elements, self-lubricating elements, date stamps, gap pointers, tube electrodes.

The Company

Reliability in three business sectors.

EVOLT is a family enterprise active in three business sectors – precision CNC manufacturing, cleaning-maintenance, and selling standard tool items. It has been offering solutions to its clients since the beginning of the 2000s. In the field of cleaning and maintenance, and in the trading of tool elements we have established a satisfied clientele in addition to Hungary also in the neighbouring countries. We have developed by today into a supplier partner even in the international arena in the field of the indexed 5-axis and simultaneous 5-axis manufacturing of precision, complex and extremely complex parts/workpieces.

Our everyday life is value creation!

The Quality

Quality assurance with an innovative measurement technology

hyperMILL® PROBING We implement our measurements directly on the machine tool!

Carrying out the measurements during the process makes it possible to recognise the manufacturing defects especially in the case of NC machining at an early time, and to react on them immediately. With this we shorten the lead time and at the same time we ensure the quality of the parts. 3D point measurement is a special feature, with the aid of which we may touch surfaces of arbitrary forms, and we may carry out this measurement even on our simultaneous 5-axis machining machines.

Its advantages are the following:

- Improved quality and process control

- Shorter lead time

- Accelerated quality assuring process

- Enhanced safety and less scrap

We work according to quality management systems MSZ EN ISO 9001:2015 and MSZ EN ISO 14001:2015. Test our quality and our delivery reliability!

Career

During the past years, with our everyday common work, we have established lots of values for our clients in Hungary and abroad. We believe at our family-owned company that our continuous growth and our successes are due to our committed team. For this reason, if you are a success oriented, open-minded team player or you looking for challenges and innovative technologies, you would like to test yourself in the international field, you would like to also develop yourself with the aid of further training events and education, and you wish to work in a secure and stable environment, we look forward to you as the next member of our team.